Abaqus/Standard to Abaqus/Explicit co-simulation | ||

| ||

ProductsAbaqus/StandardAbaqus/Explicit

Features tested

The following sections describe verification problems for:

lockstep co-simulation of Abaqus/Explicit with Abaqus/Standard nonlinear dynamic procedures;

subcycling co-simulation of Abaqus/Explicit with Abaqus/Standard nonlinear dynamic procedures;

subcycling co-simulation of Abaqus/Explicit with Abaqus/Standard nonlinear quasi-static procedures; and

various cases of modeling techniques and model attributes applied at the co-simulation interface between the Abaqus/Explicit and Abaqus/Standard jobs.

Lockstep co-simulation of Abaqus/Standard nonlinear dynamic procedures to Abaqus/Explicit procedures

Elements tested

B31

C3D8I

C3D8

C3D4

S4R

T3D2

Features tested

The fidelity and numerical stability of results obtained using a lockstep Abaqus/Standard to Abaqus/Explicit co-simulation for a model undergoing dynamic large-deformation motion.

Problem description

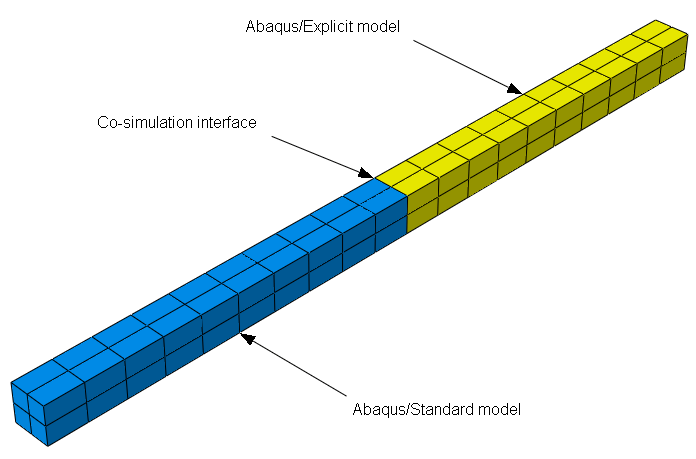

The problem is a simple beam subjected to an excitation force at the end (see Figure 1).

Model:

The model consists of Abaqus/Standard and Abaqus/Explicit components of a beam of length 20, width 1, and height 1.

Mesh:

A regular brick mesh is used for the continuum and shell element models.

Material:

A linear elastic material definition is used.

Boundary conditions:

The Abaqus/Standard portion of the beam is fully embedded at its end.

Loading:

The Abaqus/Explicit portion of the beam has a load applied transverse to the beam axis.

Co-simulation definition

Each model uses the lockstep method on the co-simulation controls.

Lockstep co-simulation algorithm description

When using the lockstep method, Abaqus/Standard and Abaqus/Explicit will advance their respective solution using the same time incrementation.

Results and discussion

In each case there is generally good agreement between the Abaqus/Standard to Abaqus/Explicit co-simulation results and the Abaqus/Explicit results.

Input files

- beam_dyntodyn_lockstep_std.inp

-

B31 Abaqus/Standard analysis.

- beam_dyntodyn_lockstep_xpl.inp

-

B31 Abaqus/Explicit analysis.

- beam_dyntodyn_lockstep_config.xml

-

Co-simulation configuration file.

- beam_fullxpl.inp

-

B31 Abaqus/Explicit reference analysis.

- contbeam_dyntodyn_lockstep_std.inp

-

C3D8I Abaqus/Standard analysis.

- contbeam_dyntodyn_lockstep_xpl.inp

-

C3D8I Abaqus/Explicit analysis.

- contbeam_dyntodyn_lockstep_config.xml

-

Co-simulation configuration file.

- contbeam_fullxpl.inp

-

C3D8I Abaqus/Explicit reference analysis.

- contbeam_rot_dyntodyn_lockstep_std.inp

-

B31, C3D8I, S4R Abaqus/Standard analysis.

- contbeam_rot_dyntodyn_lockstep_xpl.inp

-

B31, C3D8I, S4R Abaqus/Explicit analysis.

- contbeam_rot_dyntodyn_lockstep_config.xml

-

Co-simulation configuration file.

- contbeam_rot_fullxpl.inp

-

B31, C3D8I, S4R Abaqus/Explicit reference analysis.

- truss_dyntodyn_lockstep_std.inp

-

T3D2 Abaqus/Standard analysis.

- truss_dyntodyn_lockstep_xpl.inp

-

T3D2 Abaqus/Explicit analysis.

- truss_dyntodyn_lockstep_config.xml

-

Co-simulation configuration file.

- truss_fullxpl.inp

-

T3D2 Abaqus/Explicit reference analysis.

- contbeam_dmesh_dyntodyn_lock_std.inp

-

C3D4 Abaqus/Standard analysis.

- contbeam_dmesh_dyntodyn_lock_xpl.inp

-

C3D8 Abaqus/Explicit analysis.

- contbeam_dmesh_dyntodyn_lock_config.xml

-

Co-simulation configuration file.

- contbeam_dmesh2_dyntodyn_lock_std.inp

-

C3D8 Abaqus/Standard analysis.

- contbeam_dmesh2_dyntodyn_lock_xpl.inp

-

C3D4 Abaqus/Explicit analysis.

- contbeam_dmesh2_dyntodyn_lock_config.xml

-

Co-simulation configuration file.

![]()

Subcycling co-simulation of Abaqus/Standard nonlinear dynamic procedures to Abaqus/Explicit procedures

Elements tested

B31

C3D8I

C3D8

C3D4

S4R

T3D2

Features tested

The fidelity and numerical stability of results obtained using a subcycling Abaqus/Standard to Abaqus/Explicit co-simulation for a model undergoing dynamic large-deformation motion.

Problem description

The problem is a simple beam subjected to severe excitation force (see Figure 1).

Model:

The model consists of Abaqus/Standard and Abaqus/Explicit components of a beam of length 20, width 1, and height 1.

Mesh:

A regular brick mesh is used for the continuum and shell element models.

Material:

A linear elastic material definition is used.

Boundary conditions:

The Abaqus/Standard portion of the beam is fully embedded at its end.

Loading:

The Abaqus/Explicit portion of the beam has a load applied transverse to the beam axis.

Co-simulation definition

Each model uses the subcycle method on the co-simulation controls.

Subcycling co-simulation algorithm description

When using the subcycle method, Abaqus/Standard and Abaqus/Explicit will advance their respective solutions using time incrementation appropriate to their solution.

Results and discussion

In each case there is generally good agreement between the Abaqus/Standard to Abaqus/Explicit co-simulation results and the Abaqus/Explicit results.

Input files

- beam_dyntodyn_subcycle_std.inp

-

B31 Abaqus/Standard analysis.

- beam_dyntodyn_subcycle_xpl.inp

-

B31 Abaqus/Explicit analysis.

- beam_dyntodyn_subcycle_config.xml

-

Co-simulation configuration file.

- beam_fullxpl.inp

-

B31 Abaqus/Explicit reference analysis.

- contbeam_dyntodyn_subcycle_std.inp

-

C3D8I Abaqus/Standard analysis.

- contbeam_dyntodyn_subcycle_xpl.inp

-

C3D8I Abaqus/Explicit analysis.

- contbeam_dyntodyn_subcycle_config.xml

-

Co-simulation configuration file.

- contbeam_fullxpl.inp

-

C3D8I Abaqus/Explicit reference analysis.

- contbeam_rot_dyntodyn_subcycle_std.inp

-

B31, C3D8I, S4R Abaqus/Standard analysis.

- contbeam_rot_dyntodyn_subcycle_xpl.inp

-

B31, C3D8I, S4R Abaqus/Explicit analysis.

- contbeam_rot_dyntodyn_subcycle_config.xml

-

Co-simulation configuration file.

- contbeam_rot_fullxpl.inp

-

B31, C3D8I, S4R Abaqus/Explicit reference analysis.

- truss_dyntodyn_subcycle_std.inp

-

T3D2 Abaqus/Standard analysis.

- truss_dyntodyn_subcycle_xpl.inp

-

T3D2 Abaqus/Explicit analysis.

- truss_dyntodyn_subcycle_config.xml

-

Co-simulation configuration file.

- truss_fullxpl.inp

-

T3D2 Abaqus/Explicit reference analysis.

- contbeam_dmesh_dyntodyn_sub_std.inp

-

C3D4 Abaqus/Standard analysis.

- contbeam_dmesh_dyntodyn_sub_xpl.inp

-

C3D8 Abaqus/Explicit analysis.

- contbeam_dmesh_dyntodyn_sub_config.xml

-

Co-simulation configuration file.

- contbeam_dmesh2_dyntodyn_sub_std.inp

-

C3D8 Abaqus/Standard analysis.

- contbeam_dmesh2_dyntodyn_sub_xpl.inp

-

C3D4 Abaqus/Explicit analysis.

- contbeam_dmesh2_dyntodyn_sub_config.xml

-

Co-simulation configuration file.

- contbeam_dyntodyn_fact_std.inp

-

C3D8I Abaqus/Standard analysis.

- contbeam_dyntodyn_fact_xpl.inp

-

C3D8I Abaqus/Explicit analysis.

- contbeam_dyntodyn_fact_config.xml

-

Co-simulation configuration file.

- contbeam_dmesh_dyntodyn_fact_std.inp

-

C3D4 Abaqus/Standard analysis.

- contbeam_dmesh_dyntodyn_fact_xpl.inp

-

C3D8 Abaqus/Explicit analysis.

- contbeam_dmesh_dyntodyn_fact_config.xml

-

Co-simulation configuration file.

![]()

Subcycling co-simulation of Abaqus/Standard nonlinear static procedures to Abaqus/Explicit procedures

Elements tested

B31

C3D8I

C3D8

C3D4

S4R

T3D2

Features tested

The fidelity and numerical stability of results obtained using subcycling Abaqus/Standard quasi-static procedures to Abaqus/Explicit co-simulation for a model undergoing quasi-static deformation.

Problem description

The problem is a simple beam subjected to quasi-static loading (see Figure 1).

Model:

The model consists of Abaqus/Standard and Abaqus/Explicit components of a beam of length 20, width 1, and height 1.

Mesh:

A regular brick mesh is used for the continuum and shell element models.

Material:

A linear elastic material definition is used.

Boundary conditions:

The Abaqus/Standard portion of the beam is fully embedded at the free end.

Loading:

The Abaqus/Explicit portion of the beam has a load applied transverse to the beam axis.

Co-simulation definition

Each model uses the subcycle method on the co-simulation controls.

Subcycling co-simulation algorithm description

When using the subcycle method, Abaqus/Standard and Abaqus/Explicit will advance their respective solutions using time incrementation appropriate to their solution.

Results and discussion

In each case there is generally good agreement between the Abaqus/Standard to Abaqus/Explicit co-simulation results and the Abaqus/Explicit results.

Input files

- contbeam_statodyn_subcycle_std.inp

-

C3D8I Abaqus/Standard analysis.

- contbeam_statodyn_subcycle_xpl.inp

-

C3D8I Abaqus/Explicit analysis.

- contbeam_statodyn_subcycle_config.xml

-

Co-simulation configuration file.

- contbeam_quasistatic_fullxpl.inp

-

C3D8I Abaqus/Explicit reference analysis.

- contbeam_rot_statodyn_subcycle_std.inp

-

B31, C3D8I, S4R Abaqus/Standard analysis.

- contbeam_rot_statodyn_subcycle_xpl.inp

-

B31, C3D8I, S4R Abaqus/Explicit analysis.

- contbeam_rot_statodyn_fact_config.xml

-

Co-simulation configuration file.

- contbeam_rot_quasistatic_fullxpl.inp

-

B31, C3D8I, S4R Abaqus/Explicit reference analysis.

- truss_statodyn_subcycle_std.inp

-

T3D2 Abaqus/Standard analysis.

- truss_statodyn_subcycle_xpl.inp

-

T3D2 Abaqus/Explicit analysis.

- truss_statodyn_subcycle_config.xml

-

Co-simulation configuration file.

- truss_fullxpl.inp

-

T3D2 Abaqus/Explicit reference analysis.

- contbeam_dmesh_statodyn_sub_std.inp

-

C3D4 Abaqus/Standard analysis.

- contbeam_dmesh_statodyn_sub_xpl.inp

-

C3D8 Abaqus/Explicit analysis.

- contbeam_dmesh_statodyn_sub_config.xml

-

Co-simulation configuration file.

- contbeam_dmesh2_statodyn_sub_std.inp

-

C3D8 Abaqus/Standard analysis.

- contbeam_dmesh2_statodyn_sub_xpl.inp

-

C3D4 Abaqus/Explicit analysis.

- contbeam_dmesh2_statodyn_sub_config.xml

-

Co-simulation configuration file.

- contbeam_rot_statodyn_fact_std.inp

-

B31, C3D8I, S4R Abaqus/Standard analysis.

- contbeam_rot_statodyn_fact_xpl.inp

-

B31, C3D8I, S4R Abaqus/Explicit analysis.

- contbeam_rot_statodyn_fact_config.xml

-

Co-simulation configuration file.

- contbeam_dmesh_statodyn_fact_std.inp

-

C3D4 Abaqus/Standard analysis.

- contbeam_dmesh_statodyn_fact_xpl.inp

-

C3D8 Abaqus/Explicit analysis.

- contbeam_dmesh_statodyn_fact_config.xml

-

Co-simulation configuration file.

![]()

Model attribute tests for Abaqus/Standard to Abaqus/Explicit co-simulation

Elements tested

B21

C3D8I

C3D4

SFM3D4R

Features tested

The proper operation of Abaqus/Standard to Abaqus/Explicit co-simulation is confirmed for cases involving specific modeling attributes.

Problem description

Each problem considered is a variation of those described in Lockstep co-simulation of Abaqus/Standard nonlinear dynamic procedures to Abaqus/Explicit procedures. Particular variations are listed in the input file description.

Results and discussion

In each case the results confirm that Abaqus/Standard to Abaqus/Explicit co-simulation operates correctly with particular modeling attributes employed.

Input files

- beam_2d_dyntodyn_subcycle_std.inp

-

B21 Abaqus/Standard analysis.

- beam_2d_dyntodyn_subcycle_xpl.inp

-

B21 Abaqus/Explicit analysis.

- beam_2d_dyntodyn_subcycle_config.xml

-

Co-simulation configuration file.

- contbeam_substruc_subcycle_std.inp

-

C3D8I Abaqus/Standard analysis.

- contbeam_substructure_gen.inp

-

C3D8I Abaqus/Standard substructure generation.

- contbeam_substruc_subcycle_std.inp

-

C3D8I Abaqus/Explicit analysis.

- contbeam_substruc_subcycle_config.xml

-

Co-simulation configuration file.

- contbeam_dyntodyn_mass_scale_std.inp

-

C3D8I Abaqus/Standard analysis.

- contbeam_dyntodyn_mass_scale_xpl.inp

-

C3D8I Abaqus/Explicit analysis with mass scaling.

- contbeam_dyntodyn_mass_scale_config.xml

-

Co-simulation configuration file.

- tie_dyntodyn_lockstep_std.inp

-

C3D4, SFM3D4R Abaqus/Standard analysis.

- tie_dyntodyn_lockstep_xpl.inp

-

C3D4, SFM3D4R Abaqus/Explicit analysis.

- tie_dyntodyn_lockstep_config.xml

-

Co-simulation configuration file.

- tie_dyntodyn_subcycle_std.inp

-

C3D4, SFM3D4R Abaqus/Standard analysis.

- tie_dyntodyn_subcycle_xpl.inp

-

C3D4, SFM3D4R Abaqus/Explicit analysis.

- tie_dyntodyn_subcycle_config.xml

-

Co-simulation configuration file.