Finite-sliding contact between a deformable body and a meshed rigid surface | ||

| ||

ProductsAbaqus/Standard

Features tested

CONTACT PAIR DSURF, RSURF DSURF is a surface on the deformable body, and RSURF is a rigid surface meshed with either rigid elements or deformable elements declared as rigid.

Two-dimensional meshed rigid surfaces

Elements tested

B21

CPS4R

R2D2

T2D2

Problem description

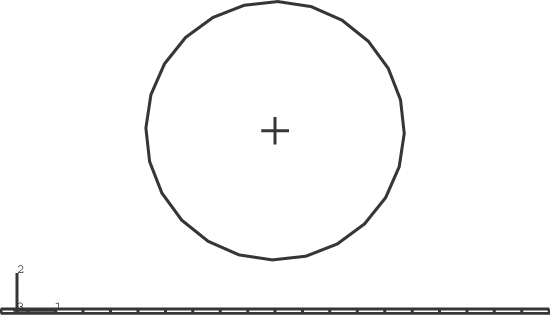

These tests verify that two-dimensional meshed rigid surfaces are properly generated and that the surface orientation and normal smoothing are correct. The first problem involves forming an elastic beam around a closed meshed rigid surface. This closed surface can be thought of as a pipe cross-section. The second problem is similar to the first but with user-defined normals.

The surface, which is assumed to be rigid, is meshed with 2-node rigid elements. The beam, which is 6 inches long and 0.05 inches wide, is modeled with 20 CPS4R solid elements. Its original position with respect to the first rigid surface is shown in Figure 1. It is assumed to be elastic with a Young's modulus of 30.0 × 106 lb/in2 and a Poisson's ratio of 0.3. Surfaces defined on the deformable body and the rigid body are paired together to enforce contact.

The analysis is made up of two parts. The first part establishes contact between the beam and the rigid surface by moving the two ends of the beam upward so that contact is firmly established while constraining the beam ends horizontally. The second part involves releasing the beam end constraints and applying a pressure load to the bottom surface of the beam to mold it firmly around the pipe section. A pressure of 1000 lb/in2 is applied in the first problem, while a pressure of 2000 lb/in2 is applied in the second problem.

Results and discussion

The deformable body conforms to the shape of the rigid body.

Input files

- ei22ssr1.inp

-

Two-dimensional rigid surface consisting of rigid elements with default Abaqus-generated normals.

- ei22ssr1_surf.inp

-

Two-dimensional rigid surface consisting of rigid elements with default Abaqus-generated normals using surface-to-surface contact.

- ei22ssr2.inp

-

Two-dimensional rigid surface consisting of rigid elements with user-specified normals.

- ei22srb2.inp

-

Bèzier rigid surfaces used to model contact. (This capability is no longer supported.)

- ei22srb2_surf.inp

-

Bèzier rigid surfaces used to model contact with surface-to-surface approach. (This capability is no longer supported.)

- ed22ssr1.inp

-

Two-dimensional rigid surface consisting of beam elements declared as rigid with default Abaqus-generated normals.

- ed22ssr2.inp

-

Two-dimensional rigid surface consisting of beam elements declared as rigid with user-specified normals.

![]()

Three-dimensional meshed rigid surfaces

Elements tested

R3D3

S3R

S4

S4R

Problem description

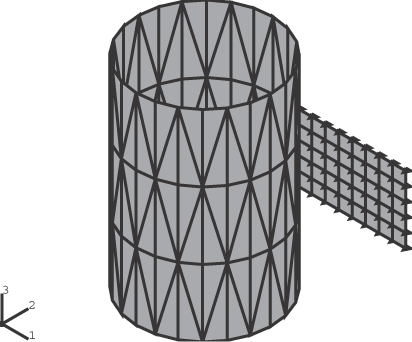

This test verifies that three-dimensional meshed rigid surfaces are properly generated and that the search algorithm used to determine the closest distance to such surfaces is robust. The problem consists of the forming of an elastic sheet around a cylinder.

The cylinder is assumed to be rigid and has a radius of 5 inches. The original mesh with the meshed rigid surface is shown in Figure 2.

The sheet has dimensions 10 inches by 5 inches and is modeled with fifty 4-node S4R or S4 shell elements. ENCASTRE-type boundary conditions are applied to the sheet on one side. A pressure load of 700 lb/in2 is applied on its surface to form it around the cylinder. The sheet is assumed to be elastic with Young's modulus of 3 × 106 lb/in2 and Poisson's ratio of 0.3. The sheet is 0.25 inches thick.

Surfaces defined on the rigid cylinder and deformable sheet are paired together to enforce contact.

Results and discussion

The deformable body conforms to the shape of the rigid body.

Input files

- eig1ssr3.inp

-

Three-dimensional rigid surface meshed with rigid elements. Contact with S4R elements.

- eig1ssr3_surf.inp

-

Three-dimensional rigid surface meshed with rigid elements. Surface-to-surface contact with S4R elements.

- eig1ssr4.inp

-

Three-dimensional rigid surface meshed with rigid elements. Contact with S4 elements.

- eig1srb3.inp

-

Bèzier rigid surfaces used to model contact. (This capability is no longer supported.)

- edg1ssr3.inp

-

Three-dimensional rigid surface meshed with shell elements declared as rigid. Contact with S4R elements.

- edg1ssr4.inp

-

Three-dimensional rigid surface meshed with shell elements declared as rigid. Contact with S4 elements.