Overview of Eulerian analyses | ||

| ||

Context:

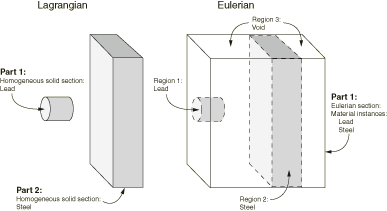

The techniques for modeling pure Eulerian analyses in Abaqus/CAE are very different than those used to model pure Lagrangian analyses. Most notably, instead of defining several parts and assembling them into a complete model, Eulerian models typically consist of a single Eulerian part. This part, which can be arbitrary in shape, represents the domain within which Eulerian materials can flow. The geometry of bodies in the model is not necessarily defined by the Eulerian part; instead, materials are assigned to different regions within the Eulerian part instance to define the body geometries.

Figure 1 compares the same model created using Lagrangian and Eulerian techniques. In the Lagrangian model, two parts are modeled, and each part is assigned a unique section referencing a material. In the Eulerian model, a single Eulerian part is modeled and assigned an Eulerian section. The Eulerian section defines the materials that can be present within the part. Materials are then assigned to different regions within the instanced part; any region without a material assignment is treated as a void with no material properties.

The Eulerian analysis technique can be coupled with traditional Lagrangian techniques to extend the simulation functionality in Abaqus:

-

Arbitrary Lagrangian-Eulerian (ALE) adaptive meshing is a technique that combines features of Lagrangian and Eulerian analysis within the same part mesh. ALE adaptive meshing is typically used to control element distortion in Lagrangian parts undergoing large deformations, such as in a forming analysis. Most ALE adaptive meshing analyses can also be performed as pure Eulerian analyses, but some of the features associated with a Lagrangian mesh will be lost; for a more detailed comparison, see About ALE adaptive meshing.

-

Coupled Eulerian-Lagrangian (CEL) analysis allows Eulerian and Lagrangian bodies within the same model to interact. Coupled Eulerian-Lagrangian analysis is typically used to model the interactions between a solid body and a yielding or fluid material, such as a Lagrangian drill traveling through Eulerian soil or an Eulerian gas inflating a Lagrangian airbag. Eulerian-Lagrangian analysis is discussed in Assembling coupled Eulerian-Lagrangian models in Abaqus/CAE.

Viewing the results of Eulerian analyses requires some special techniques in the Visualization module. These techniques are discussed in detail in Viewing output from Eulerian analyses.

The procedure for creating Eulerian models in Abaqus/CAE involves the following general steps:

An example of a basic Eulerian model created in Abaqus/CAE is provided in Eulerian analysis of a collapsing water column. More complicated Eulerian modeling procedures, including complex material assignments and coupled Eulerian-Lagrangian interactions, are illustrated in Impact of a water-filled bottle.