Demand wettability of a porous medium: coupled analysis | ||

| ||

ProductsAbaqus/Standard

In this example we consider a one-dimensional “demand wettability” test, in which fluid is made available to the material at a certain location and the material is allowed to absorb as much fluid as it can. In this example we consider a column of material and allow it to absorb fluid at the bottom. The column is kinematically constrained in the horizontal direction so that all deformation will be in the vertical direction; in this sense the problem is one-dimensional. We investigate two cases: one in which the material contains a large number of gel particles that entrap fluid and, as a result, enhance the fluid retention capability of the material; and the other in which the material does not contain gel. Additional tests are provided that illustrate the use of solution mapping along with modeling of gel particles.

Problem description

The column of material is 50.8 mm high. We model the problem with 10 CPE8RP plane strain elements. In addition, input files containing different element types are included for verification purposes. The mesh is shown in Figure 1. We constrain all horizontal displacements and the vertical displacements at the bottom of the column.

![]()

Material

The properties pertaining to the partially saturated flow behavior of the material are the same as those used in Partially saturated flow in a porous medium. For the mechanical properties we assume the material is elastic, with Young's modulus 10000 Pa and Poisson's ratio 0.0. The mechanical properties of the gel particles are assumed to be similar to those of a fluid since they are mostly made up of absorbed fluid. Therefore, a bulk modulus of 2.0 × 109 Pa is specified for the gel.

The initial conditions for pore pressure and saturation are assumed to be those at the beginning of the absorption curve, so the initial saturation is 0.05 and the initial pore pressure is −10000 Pa.

![]()

Loading and controls

In the first step of the analysis we establish stress equilibrium in the original configuration of the column of material. A stress of 500 Pa is applied to the mesh to balance the initial pore pressure and saturation conditions. The effective stress principle (s is the saturation and u is the pore pressure) then gives zero effective stresses, , for the undeformed configuration.

The “loading” consists of prescribing essentially zero pore pressure (corresponding to full saturation) at the bottom of the column. This is based on the assumption that, in the demand wettability test, the sample has available to it as much fluid as necessary to cause saturation at that point. This boundary condition is held fixed for 3000 seconds to model the fluid acquisition process.

The analysis is performed with the transient soils consolidation procedure using automatic time incrementation. The pore pressure tolerance that controls the automatic incrementation is set to a large value since we expect the nonlinearity of the material to restrict the size of the time increments during the transient stages of the analysis and we do not wish to impose any further control on the accuracy of the time integration.

The choice of initial time increment in these transient partially saturated flow problems is important for some element types, to avoid spurious solution oscillations. This is discussed in Partially saturated flow in a porous medium. As discussed in Coupled pore fluid diffusion and stress analysis, the criterion for a minimum usable time increment in partial-saturation conditions is

where is the specific weight of the wetting liquid, is the initial porosity of the material, k is the fully saturated permeability of the material, is the permeability-saturation relationship, is the rate of change of saturation with respect to pore pressure as defined in the absorption/exsorption material behavior (Sorption), and is a typical element dimension. For our model we have 5.08 mm (the size of an element side), 1.0 × 104 N/m3, 3.7 × 10−4 m/sec, , and 5/6. Adjacent to where we apply the fully saturated boundary condition, elements will span a region from initial to full saturation early in the transient. A conservative estimate of the minimum time increment is found by choosing the initial saturation of 0.05. From this, we compute , , and a value of of about 70 sec. We find, in practice, that an initial increment of 50 sec is adequate to avoid oscillations in this problem. For the remaining input files the initial time increment is chosen as discussed in Partially saturated flow in a porous medium since we have the same material properties and spatial discretization.

In this analysis the prevailing pore pressure in the medium approaches the magnitude of the stiffness of the material skeleton elastic modulus. When reduced-integration elements are used in such cases, the default choice for the hourglass stiffness control, which is based on a scaling of skeleton material constitutive parameters, may not be adequate to control hourglassing in the presence of the relatively large pore pressure fields. An appropriate hourglass control setting in these cases should scale with the expected magnitude of pore pressure changes over an element and must be defined explicitly by the user.

Geometric nonlinearities are considered in the analysis since we expect large deformations due to the growth of the gel particles.

![]()

Results and discussion

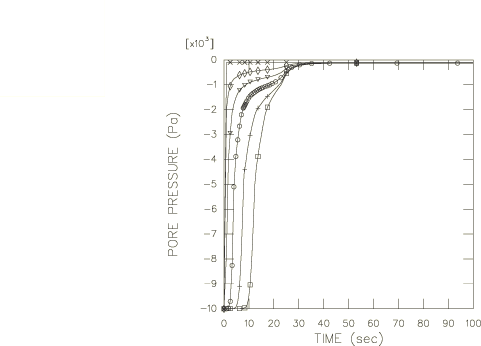

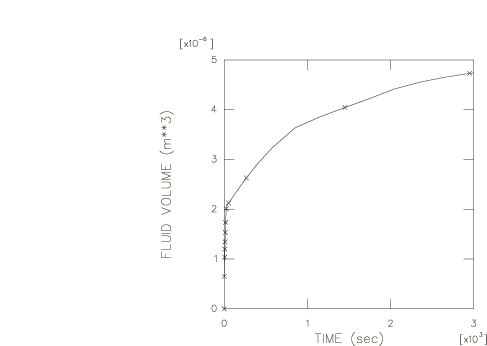

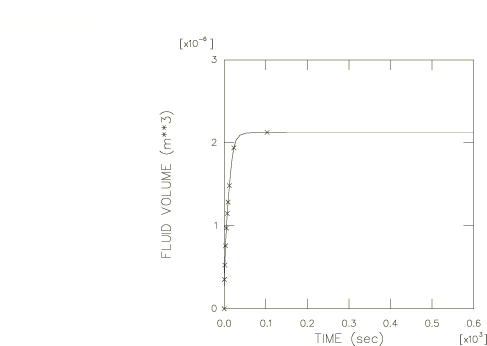

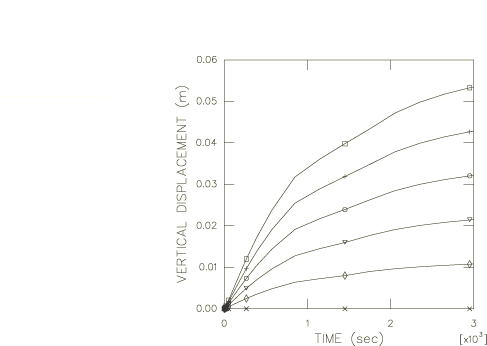

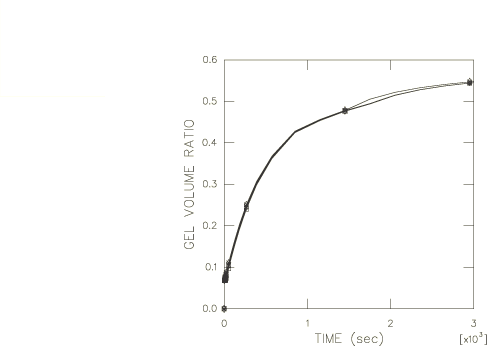

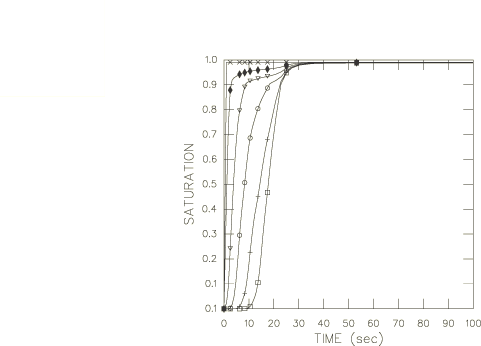

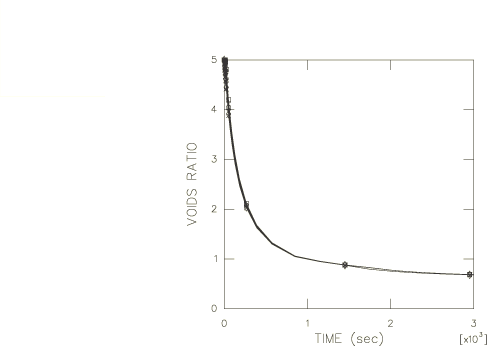

In the case of the specimen without gel we expect the material to absorb fluid until it is fully saturated, without any significant change in volume. However, in the case of the specimen containing gel particles, we expect a significant volume increase associated with the swelling of the gel particles as they entrap fluid. Figure 2 shows the time history of the pore pressures at six nodes along the height of the column of material; this is identical for the specimens with and without gel. The time history of the volume of fluid absorbed by the two specimens is shown in Figure 3 for the case of the material with gel and Figure 4 for the material without gel: the specimen containing gel absorbs roughly twice as much fluid (which is consistent with the fact that it roughly doubles in volume as the gel expands during absorption). Time histories of vertical displacement for the material with gel are shown in Figure 5. The material without gel does not show a significant change in volume. The growth of the gel particles in the case of the sample with gel is shown in Figure 6, where we plot the time histories of the ratio of the volume of gel in the specimen to the total volume of the specimen at the six integration points closest to the six nodes for which the pore pressure histories are plotted. In Figure 7 we show time histories of free fluid saturation. These histories are identical for the two samples. The void ratio for the sample without gel remains close to its initial value of 5.0 throughout the test, whereas in the sample with gel the void ratio decreases to values below 1.0, as shown in the time histories of Figure 8. This is a result of the void space available for free fluid flow decreasing as the gel particles swell.

Moisture swelling of the soil skeleton is added to the material behavior for verification purposes. With the addition of the moisture swelling more fluid volume is absorbed into the specimen, the specimen becomes longer when compared to the model without moisture swelling, and it takes more time to saturate the specimen. These observations are consistent with the added swelling of the soil skeleton in the presence of the moisture.

![]()

Input files

- demandwetpormed_c3d4p_gel.inp

Element type C3D4P.

- demandwetpormed_c3d4ph_gel.inp

Element type C3D4PH.

- demandwetpormed_c3d4pt_gel.inp

Element type C3D4PT.

- demandwetpormed_c3d4pht_gel.inp

Element type C3D4PHT.

- demandwetpormed_c3d6p_gel.inp

Element type C3D6P.

- demandwetpormed_c3d6ph_gel.inp

Element type C3D6PH.

- demandwetpormed_c3d6pt_gel.inp

Element type C3D6PT.

- demandwetpormed_c3d6pht_gel.inp

Element type C3D6PHT.

- demandwetpormed_c3d8p_gel.inp

Element type C3D8P.

- demandwetpormed_c3d8p_gel_post.inp

POST OUTPUT analysis.

- demandwetpormed_c3d8rp_gel.inp

Element type C3D8RP.

- demandwetpormed_cax4p_gel.inp

Element type CAX4P.

- demandwetpormed_cpe4ph_gel.inp

Element type CPE4PH.

- demandwetpormed_cpe4ph_gel_post.inp

POST OUTPUT analysis.

- demandwetpormed_cpe8rp_gel.inp

Sample containing gel particles (element type CPE8RP).

- demandwetpormed_cpe8rp_swell.inp

Adds moisture swelling to the material behavior in demandwetpormed_cpe8rp_gel.inp.

- demandwetpormed_cpe8rp_nogel.inp

Same as demandwetpormed_cpe8rp_gel.inp, except that GEL is removed.

- demandwetpormed_cpe8rp_gel_anc.inp

MAP SOLUTION ancestor analysis.

- demandwetpormed_cpe8rp_gel_des.inp

MAP SOLUTION descendant analysis.

![]()

Figures