Contact controls for general contact in Abaqus/Explicit | |||||||||

|

| ||||||||

ProductsAbaqus/Explicit

Scaling default penalty stiffnesses

The general contact algorithm uses a penalty method to enforce the contact constraints (see Contact constraint enforcement methods in Abaqus/Explicit for more information). The “spring” stiffness that relates the contact force to the penetration distance is chosen automatically by Abaqus/Explicit, such that the effect on the time increment is minimal yet the allowed penetration is not significant in most analyses. Significant penetrations may develop in an analysis if any of the following factors are present:

Displacement-controlled loading

Materials at the contact interface that are purely elastic or stiffen with deformation

Deformable elements (especially membrane and surface elements) that have relatively little mass of their own and are constrained via methods other than boundary conditions (for example, connectors) involved in contact

Rigid bodies that have relatively little mass or rotary inertia of their own and are constrained via methods other than boundary conditions (for example, connectors) involved in contact

See The Hertz contact problem for an example in which the first two of these factors combine such that the contact penetrations with the default penalty stiffness are significant.

You can specify a scale factor by which to modify penalty stiffnesses for specified interactions within the general contact domain. This scaling may affect the automatic time incrementation. Use of a large scale factor is likely to increase the computational time required for an analysis because of the reduction in the time increment that is necessary to maintain numerical stability (see Contact constraint enforcement methods in Abaqus/Explicit for further discussion).

The user-specified (variable) mass scaling does not take into account the effect of contact when it computes the necessary increase of mass. In general, this effect is not significant as the default penalty stiffness will decrease the stable time increment only by very small amounts. However, if high penalty scale factors are specified, the stable time increment could be reduced significantly despite the specified mass scaling.

The surface names used to specify the regions where nondefault penalty stiffness should be assigned do not have to correspond to the surface names used to specify the general contact domain. In many cases the contact interaction will be defined for a large domain, while a nondefault penalty stiffness will be assigned to a subset of this domain. If the surfaces to which a nondefault penalty stiffness is assigned fall outside the general contact domain, the controls assignment will be ignored. The last assignment will take precedence if the specified regions overlap.

Input File Usage

CONTACT CONTROLS ASSIGNMENT, TYPE=SCALE PENALTY surface_1, surface_2, scale_factor

This option must be used in conjunction with the CONTACT option. It should appear at most once per step; the data line can be repeated as often as necessary to assign penalty stiffness scale factors to different regions. If the first surface name is omitted, a default surface that encompasses the entire general contact domain is assumed. If the second surface name is omitted or is the same as the first surface name, the specified contact controls are assigned to contact interactions between the first surface and itself. Keep in mind that surfaces can be defined to span multiple unattached bodies, so self-contact is not limited to contact of a single body with itself.

![]()

Control of nodal erosion

You can control whether contact nodes remain in the contact domain after all the surrounding faces and edges have eroded due to element failure. By default, these nodes remain in the contact domain and act as free-floating point masses that can experience contact with faces that are still part of the contact domain. You can specify that nodes of element-based surfaces should erode (i.e., be removed from the contact domain) once all contact faces and contact edges to which they are attached have eroded. Nodes that you include in the contact domain only with node-based surfaces are never removed from the contact domain.

Computational cost can increase as a result of free-flying nodes if nodal erosion is not specified, particularly for analyses conducted in parallel. The increased computational cost is related to the likelihood of free-flying nodes moving far away from the elements that remain active, which stretches the volume of the contact domain and thereby tends to increase contact search costs as well as the cost of communication between processors in parallel analysis. However, contact involving free-flying nodes can contribute significant momentum transfer in some cases, which will not be accounted for if nodal erosion is specified.

Input File Usage

CONTACT CONTROLS ASSIGNMENT, NODAL EROSION=NO

This option must be used in conjunction with the CONTACT option. This parameter setting applies to the entire general contact domain.

![]()

Activating the nondefault tracking algorithm for node-to-face contact

A nondefault contact tracking algorithm is available that utilizes more local topological and geometric information in tracking contact between nodes and faces. This algorithm may lead to more robust contact tracking in certain modeling situations, for instance during the inflation event of a folded air-bag.

The tracking algorithm is activated on a surface-by-surface basis. You must specify the surface name for which the tracking algorithm needs to be activated. All contact interactions in the contact domain in which nodes of the specified surface contact faces belonging to either the surface itself (self-contact) or faces belonging to any other surface (for which node-to-face contact has not been excluded) will be tracked using the nondefault node-to-face tracking scheme.

The surface names used to specify the regions where the nondefault tracking algorithm should be used do not have to correspond to the surface names used to specify the general contact domain. In many cases the contact interaction will be defined for a large domain, while the nondefault tracking algorithm will be assigned to a subset of this domain. If the surfaces for which the nondefault tracking algorithm needs to be activated fall outside the general contact domain, the controls assignment is ignored.

Input File Usage

CONTACT CONTROLS ASSIGNMENT, TYPE=FOLD TRACKING surface_1

This option must be used in conjunction with the CONTACT option. It should appear at most once per step; the data line can be repeated as often as necessary to activate the nondefault tracking algorithm in different regions of the contact domain. If the surface name is omitted, a default surface that encompasses the entire general contact domain is assumed.

![]()

Activating the fold inversion check

If a general contact surface contains sharp folds, significant loading events (for example, those encountered during the inflation of a folded airbag) may cause one or more of the folds to invert. Inversion is most likely to occur at a fold where edge-to-edge contact has not been activated on the edges of the faces forming the fold. The presence of edge-to-edge constraints usually prevents a fold from inverting. Inversion of a fold, in the absence of edge-to-edge contact constraints, may induce errors in the node-to-face contact tracking algorithm and may result in a node that was being tracked on a face that forms part of an inverted fold getting “snagged” on the wrong side of the tracked face. To avoid such situations, it may be desirable to activate the fold inversion check for models containing sharp folds. The fold inversion check detects situations where a fold is about to invert and applies a force field to the faces forming the fold to prevent the fold from inverting.

The fold inversion check is activated on a surface-by-surface basis. You must specify the surface name for which the fold inversion check needs to be activated. If activated for a particular surface, the fold inversion check applies to all folds within that surface.

The surface names used to specify the regions where the fold inversion check should be activated do not have to correspond to the surface names used to specify the general contact domain. In many cases the contact interaction will be defined for a large domain, while the fold inversion check will be activated in a subset of this domain. If the surfaces for which the fold inversion check needs to be activated fall outside the general contact domain, the controls assignment is ignored.

Input File Usage

CONTACT CONTROLS ASSIGNMENT, TYPE=FOLD INVERSION CHECK surface_1

This option must be used in conjunction with the CONTACT option. It should appear at most once per step; the data line can be repeated as often as necessary to activate the fold inversion check in different regions of the contact domain. If the surface name is omitted, a default surface that encompasses the entire general contact domain is assumed.

![]()

Activating the default tracking algorithm for edge-to-edge contact

The default contact tracking algorithm utilizes more local information than the alternative tracking algorithm in tracking contact between edges and typically reduces the extent of global tracking required. The use of this algorithm may lead to smaller computational times in analyses that have extensive edge-to-edge contact defined (for example, during the inflation simulation of a folded airbag, where it may be desirable to activate all feature edges on the airbag membrane surface to accurately enforce contact during the inflation event).

The default tracking algorithm can be explicitly specified, though all edge-to-edge contact in the contact domain will be enforced using the default tracking algorithm if contact controls are not specified for the tracking algorithm.

Input File Usage

CONTACT CONTROLS ASSIGNMENT, TYPE=ENHANCED EDGE TRACKING (default)

This option must be used in conjunction with the CONTACT option. This parameter setting applies to the entire general contact domain.

![]()

An alternative tracking algorithm for edge-to-edge contact

An alternative contact tracking algorithm is available that utilizes less local information than the default tracking algorithm in tracking contact between edges. This algorithm typically increases the extent of global tracking required and, hence, in most analyses the computational time. When the alternative edge tracking algorithm is specified, all edge-to-edge contact in the contact domain is enforced using this algorithm.

Input File Usage

CONTACT CONTROLS ASSIGNMENT, TYPE=EDGE TRACKING

If specified, this option must be used in conjunction with the CONTACT option. This parameter setting applies to the entire general contact domain.

![]()

Control of initial overclosure resolution

By default, Abaqus/Explicit automatically adjusts the positions of surfaces to remove small initial overclosures that exist in the general contact domain in the first step of a simulation. Conflicting adjustments from separate contact definitions, boundary conditions, tie constraints, and rigid body constraints can cause incomplete resolution of initial overclosures. Initial overclosures that are not resolved by repositioning nodes are stored as initial contact offsets to avoid large contact forces at the beginning of an analysis.

Alternatively, in certain situations it may be desirable to avoid nodal adjustments altogether between a pair of surfaces and to treat all initial overclosures between the surfaces as temporary contact offsets. You can then specify the surfaces for which the initial overclosures should not be resolved by nodal adjustments and which should instead be stored as offsets.

Input File Usage

CONTACT CONTROLS ASSIGNMENT, AUTOMATIC OVERCLOSURE RESOLUTION surface_1, surface_2, STORE OFFSETS

This option must be used in conjunction with the CONTACT option. It should appear at most once per step; the data line can be repeated as often as necessary to assign a nondefault overclosure resolution method to different regions. If the first surface name is omitted, a default surface that encompasses the entire general contact domain is assumed. If the second surface name is omitted or is the same as the first surface name, the specified contact controls are assigned to contact interactions between the first surface and itself.

Effect of control of initial overclosure resolution with edge-to-edge interactions

Contact offsets are associated with individual node-facet and edge-edge combinations. Upon sliding, Abaqus/Explicit attempts to transfer contact offsets to different node-facet or edge-edge pairings, as appropriate. However, a contact offset may not be maintained (that is, may become zero) upon sliding for some cases involving multiple contacts for individual nodes or edges or surfaces with corners. Limitations causing discontinuities in the value of a contact offset across increments, which are more likely for edge-to-edge contact than node-to-surface contact, can locally degrade a solution, cause a solution to depend on the number of processors used, or cause an analysis to abort. These limitations can be avoided by more careful positioning of surface nodes by your preprocessor or, in many cases, allowing strain-free adjustments to occur.

![]()

Control of contact thickness reduction checks

By default, the general contact algorithm requires that the contact thickness does not exceed a certain fraction of the surface facet edge lengths or diagonal lengths. This fraction generally varies from 20% to 60% based on the geometry of the element and whether the element is near a shell perimeter. The general contact algorithm will scale back the contact thickness automatically where necessary without affecting the thickness used in the element computations for the underlying elements.

To check whether the thickness needs to be reduced in any particular region in the model, the contact algorithm first assigns the full thickness to each contact node, represented by a sphere centered at the node with a diameter equal to the thickness. Next, the thickness is reduced so that the spheres do not overlap with any neighboring facets that are not attached directly to the node, preventing spurious self-contact from developing. Then, the nodes on the perimeter of shells are moved a maximum of 50% of the facet size in the plane of the facet away from the perimeter to eliminate the “bull-nose” effect that occurs with the contact pair algorithm (see Assigning surface properties for contact pairs in Abaqus/Explicit). If the thickness of the shell perimeter nodes is greater than twice the maximum perimeter offset, a final thickness reduction is performed to eliminate the remainder of the “bull-nose.”

If the default thickness reductions are unacceptable in particular regions of the model, you can exclude self-contact for those regions via contact exclusion definitions (see About general contact in Abaqus/Explicit) and activate a control for the contact thickness reduction checks.

Use the following option to eliminate thickness reductions in regions of the model that are excluded from self-contact, while still reducing thickness at shell perimeters where perimeter offsets are insufficient to avoid the “bull-nose” effect:

CONTACT CONTROLS ASSIGNMENT, CONTACT THICKNESS REDUCTION=SELF

Use the following option to eliminate thickness reductions in regions of the model that are excluded from self-contact and at all shell perimeters (a “bull-nose” will form at shell perimeter nodes if the thickness is greater than twice the maximum perimeter offset):

CONTACT CONTROLS ASSIGNMENT, CONTACT THICKNESS REDUCTION=NOPERIMSELF

![]()

Consideration of incremental rotation of shell and beam thickness offsets for frictional contact

By default, slip increment calculations for friction do not account for the incremental rotation of shell and beam thickness offsets, and frictional constraints do not apply moments to nodes offset from the contact interface due to shell or beam thicknesses. In most cases the effect on the results due to neglecting these effects is small; however, it can be significant in some applications.

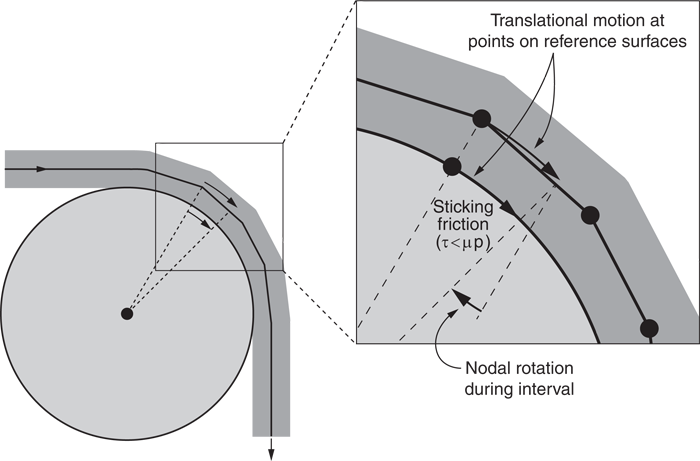

Figure 1 shows an example in which the surface thickness significantly affects slip increment calculations (and, therefore, proper enforcement of the sticking conditions). This example involves a shell surface in frictional contact with a roller guide, with no relative sliding in the contact region. The reference surface of the shell (which contains the shell nodes) is offset from the reference surface of the roller in the contact region by the half-shell thickness. As shown in the figure, some difference in tangential motion between the two reference surfaces should exist due to rotation of the thickness offset. A shell node in the sticking contact region should have slightly larger incremental displacement than that of the point of contact on the roller because the shell nodes are farther from the rotational axis; however, by default, the incremental displacement of a shell node sticking to the roller will be the same as the incremental displacement of the point of contact on the roller. To improve accuracy in such cases, you can specify that structural rotational terms should be considered.

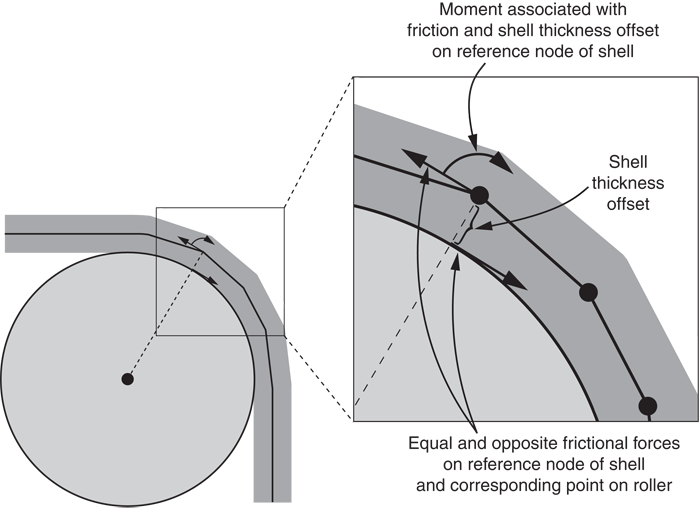

Frictional constraints should apply a moment to nodes offset from the contact interface due to shell or beam thicknesses, to oppose the net moment associated with the frictional force couple. The applied nodal moment shown in Figure 2 cancels the moment of the associated frictional force couple, such that the net force and moment associated with the frictional constraint are zero. However, by default, Abaqus/Explicit ignores this moment and generates a net moment when nodes are offset from the contact interface due to shell and beam thicknesses. To improve accuracy in such cases, you can specify that structural rotational terms should be considered.

Use the following option for frictional contact to account for incremental rotation of shell and beam thickness offsets in slip increment calculations and to apply a moment to nodes offset from the contact interface due to shell and beam thicknesses:

CONTACT CONTROLS ASSIGNMENT, ROTATIONAL TERMS=STRUCTURAL

Use the following option (default) to ignore the effects of shell and beam thickness offsets for frictional contact:

CONTACT CONTROLS ASSIGNMENT, ROTATIONAL TERMS=NONE