Contact detection for meshed models | ||

| ||

| Warning:

Unlike geometry-based searches, the reported separation between surfaces for mesh-based surfaces is not necessarily the distance between the exact points of closest approach, but rather a close approximation. If the specified search tolerance is very large compared to the characteristic element size, the accuracy of this approximation is greatly reduced. |

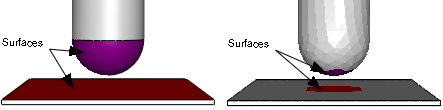

Before defining surfaces on element faces, Abaqus/CAE applies the same extension, merging, and overlap checks as with geometry faces (see Additional criteria for defining contact pairs” above). Because element faces are typically much smaller than geometric faces, you should always allow some extension of the surfaces to get ample coverage from a surface definition; Figure 1 compares the created surfaces for geometry and meshed geometry when no surface extension is allowed.

If you remesh your model, any surfaces defined on elements faces may become invalid. By extension, the interactions and constraints based on these faces also become invalid.

When assigning master and slave designations to the mesh surfaces, rigid surfaces always become the master; if the contact pair involves two rigid surfaces, the assignment of master and slave roles is arbitrary. For contact pairs involving two deformable surfaces, Abaqus/CAE considers the mesh densities on each surface; the surface with the coarser mesh becomes the master surface. If the mesh densities on the two surfaces are equivalent, the assignment of master and slave roles is arbitrary. The algorithm that assigns master and slave roles does not account for dissimilar underlying stiffness or element types; if these factors play a significant role in your contact interactions, you should review the master and slave assignments before creating an interaction. For further discussion of master and slave assignments, see Selecting surfaces used in contact pairs.

The contact detection tool does not detect contact between geometry and orphan elements or analytical surfaces and orphan elements. If your model includes part instances that have been meshed from geometry, you can use the options on the Advanced tabbed page of the contact detection dialog box to indicate whether these instances should be treated as geometry (the default) or an element mesh during the search. If your model contains instances of both geometry and orphan mesh elements, you should first mesh all of the geometries, then perform a mesh-based search to capture all possible contact pairs.

In most cases the geometry is a more faithful representation of the object being modeled than the meshed geometry. In addition, geometry-based interactions and constraints are not affected by remeshing. However, the mesh is the geometry used in the analysis. Mesh discretization can lead to slight disparities in separation distances between the two representations, which may become important in precise analyses. After performing a search, you can check individual contact pairs for disparities between the native and meshed geometry by using the option.