Generating tabular data reports for subsets of the model | ||

| ||

Context:

Since we did not create geometry sets corresponding to these regions, each of these reports will be generated using display groups whose contents are selected in the viewport. Thus, begin by creating and saving display groups for each region of interest.

Then generate the reports.

Create and save a display group containing the elements at the built-in end

In the Results Tree, double-click Display Groups.

Choose Elements from the Item list and Pick from viewport as the selection method.

Restore the option to select entities closest to the screen.

In the prompt area, set the selection method to by angle; and click the built-in face of the lug. Click Done when all the elements at the built-in face of the lug are highlighted in the viewport. In the Create Display Group dialog box, click Save Selection As. Save the display group as built-in elements.

![]()

Create and save a display group containing the nodes at the built-in end

In the Create Display Group dialog box, choose Nodes from the Item list and Pick from viewport as the selection method.

In the prompt area, set the selection method to by angle; and click the built-in face of the lug. Click Done when all the nodes on the built-in face of the lug are highlighted in the viewport. In the Create Display Group dialog box, click Save Selection As. Save the display group as built-in nodes.

![]()

Create and save a display group containing the nodes at the bottom of the hole

In the Create Display Group dialog box, click Edit Selection to select a different group of nodes.

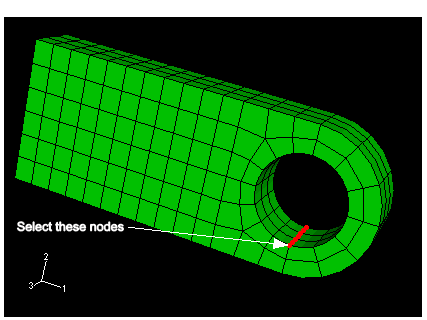

In the prompt area, set the selection method to individually; and select the nodes at the bottom of the hole in the lug, as indicated in Figure 1. Click Done when all the nodes on the bottom of the hole are highlighted in the viewport. In the Create Display Group dialog box, click Save Selection As. Save the display group as nodes at hole bottom.

Figure 1. Nodes in display group nodes at hole bottom.

![]()

Generate field data reports

In the Results Tree, click mouse button 3 on built-in elements underneath the Display Groups container. In the menu that appears, select Plot to make it the current display group.

From the main menu bar, select ReportField Output.

In the Variable tabbed page of the Report Field Output dialog box, accept the default position labeled Integration Point. Click the triangle next to S: Stress components to expand the list of available variables. From this list, select Mises and the six individual stress components: S11, S22, S33, S12, S13, and S23.

In the Setup tabbed page, name the report Lug.rpt. In the Data region at the bottom of the page, toggle off Column totals.

Click Apply.

In the Results Tree, click mouse button 3 on built-in nodes underneath the Display Groups container. In the menu that appears, select Plot to make it the current display group. (To see the nodes, toggle on Show node symbols in the Common Plot Options dialog box.)

In the Variable tabbed page of the Report Field Output dialog box, change the position to Unique Nodal. Toggle off S: Stress components, and select RF1, RF2, and RF3 from the list of available RF: Reaction force variables.

In the Data region at the bottom of the Setup tabbed page, toggle on Column totals.

Click Apply.

In the Results Tree, click mouse button 3 on nodes at hole bottom underneath the Display Groups container. In the menu that appears, select Plot to make it the current display group.

In the Variable tabbed page of the Report Field Output dialog box, toggle off RF: Reaction force, and select U2 from the list of available U: Spatial displacement variables.

In the Data region at the bottom of the Setup tabbed page, toggle off Column totals.

Click OK.

Open the file Lug.rpt in a text editor. A portion of the table of element stresses is shown below. The element data are given at the element integration points. The integration point associated with a given element is noted under the column labeled Int Pt. The bottom of the table contains information on the maximum and minimum stress values in this group of elements. The results indicate that the maximum Mises stress at the built-in end is approximately 330 MPa. Your results may differ slightly if your mesh is not identical to the one used here.

Field Output Report Source 1 --------- ODB: Lug.odb Step: LugLoad Frame: Increment 1: Step Time = 1.000 Loc 1 : Integration point values from source 1 Output sorted by column "Element Label". Field Output reported at integration points for part: LUG-1 Element Int S.Mises S.S11 S.S22 S.S33 S.S12 Label Pt @Loc 1 @Loc 1 @Loc 1 @Loc 1 @Loc 1 ------------------------------------------------------------------------------ S.S13 S.S23 @Loc 1 @Loc 1 -------------------------- 31 1 84.0567E+06 76.2075E+06 14.021E+06 -274.446E+03 -26.4339E+06 -159.756E+03 1.70193E+06 31 2 88.1108E+06 79.9769E+06 16.7815E+06 5.07167E+06 -30.8241E+06 3.045E+06 2.20251E+06 31 3 71.0378E+06 87.4511E+06 30.5433E+06 22.7759E+06 -11.8374E+06 17.114E+06 1.47033E+06 31 4 64.3978E+06 76.4473E+06 26.1412E+06 19.0617E+06 -18.6815E+06 7.36221E+06 411.436E+03 31 5 48.4688E+06 20.2162E+06 4.20669E+06 68.3536E+03 -25.8284E+06 -78.8286E+03 1.65403E+06 31 6 55.6407E+06 21.1693E+06 4.87661E+06 1.46182E+06 -30.2661E+06 796.514E+03 2.0911E+06 31 7 25.1732E+06 22.9107E+06 7.96147E+06 5.89815E+06 -10.1069E+06 4.55755E+06 1.45446E+06 31 8 32.8268E+06 19.928E+06 6.76018E+06 4.88587E+06 -16.9708E+06 1.9631E+06 378.549E+03 . . 198 1 239.655E+06 -247.046E+06 -20.9897E+06 -13.4824E+06 -38.331E+06 7.48079E+06 -1.1505E+06 198 2 237.839E+06 -235.534E+06 -13.8995E+06 2.83029E+06 -33.891E+06 -1.25472E+06 -1.57941E+06 198 3 190.507E+06 -228.049E+06 -53.1236E+06 -51.1938E+06 -37.0096E+06 20.3556E+06 -419.555E+03 198 4 219.144E+06 -259.016E+06 -65.4028E+06 -61.292E+06 -30.1529E+06 48.227E+06 -2.60239E+06 198 5 322.607E+06 -330.074E+06 -2.82071E+06 -14.7802E+06 -12.9162E+06 9.1461E+06 -189.416E+03 198 6 320.169E+06 -316.345E+06 1.80108E+06 4.87007E+06 -9.15387E+06 -4.10769E+06 -1.03378E+06 198 7 300.073E+06 -364.931E+06 -95.1687E+06 -93.2852E+06 -69.7659E+06 26.8241E+06 -343.386E+03 198 8 331.098E+06 -399.004E+06 -109.695E+06 -104.075E+06 -62.7377E+06 64.3938E+06 -2.63754E+06 Minimum 25.1732E+06 -399.004E+06 -109.695E+06 -122.144E+06 -72.2982E+06 -64.4051E+06 -2.63899E+06 At Element 33 196 198 197 98 99 99 Int Pt 8 7 8 8 4 4 4 Maximum 331.159E+06 399.073E+06 109.719E+06 122.172E+06 -9.15387E+06 64.4051E+06 2.639E+06 At Element 97 99 99 98 196 97 97 Int Pt 3 4 4 4 5 3 3How does the maximum value of Mises stress compare to the value reported in the contour plot generated earlier? Do the two maximum values correspond to the same point in the model? The Mises stresses shown in the contour plot have been extrapolated to the nodes, whereas the stresses written to the report file for this problem correspond to the element integration points. Therefore, the location of the maximum Mises stress in the report file is not exactly the same as the location of the maximum Mises stress in the contour plot. This difference can be resolved by requesting that stress output at the nodes (extrapolated from the element integration points and averaged over all elements containing a given node) be written to the report file. If the difference is large enough to be of concern, this is an indication that the mesh may be too coarse.

The table listing the reaction forces at the constrained nodes is shown below. The Total entry at the bottom of the table contains the net reaction force components for this group of nodes. The results confirm that the total reaction force in the 2-direction at the constrained nodes is equal and opposite to the applied load of −30 kN in that direction.

Field Output Report Source 1 --------- ODB: Lug.odb Step: LugLoad Frame: Increment 1: Step Time = 1.000 Loc 1 : Nodal values from source 1 Output sorted by column "Node Label". Field Output reported at nodes for part: LUG-1 Node RF.RF1 RF.RF2 RF.RF3 Label @Loc 1 @Loc 1 @Loc 1 ---------------------------------------------------------------- 3 -60.6106E-03 -118.486 -31.3131E-03 4 -60.6102E-03 -118.486 31.3133E-03 6 538.194 289.574 382.416 7 538.194 289.574 -382.416 11 -538.255 289.563 -382.329 . . 1334 5.90186E+03 216.099 1.63004E+03 1336 6.60254E+03 1.81494E+03 -45.543E-06 1337 9.81613E+03 692.328 -791.954 1339 6.35335E+03 1.7276E+03 -331.533 1340 5.90186E+03 216.098 -1.63004E+03 Minimum -9.81734E+03 -264.368 -1.63023E+03 At Node 953 258 950 Maximum 9.81613E+03 1.81556E+03 1.63022E+03 At Node 1337 951 956 Total -912.953E-06 30.0000E+03 -46.7648E-06The table showing the displacements of the nodes along the bottom of the hole (listed below) indicates that the bottom of the hole in the lug has displaced about 0.3 mm.

Field Output Report Source 1 --------- ODB: Lug.odb Step: LugLoad Frame: Increment 1: Step Time = 1.000 Loc 1 : Nodal values from source 1 Output sorted by column "Node Label". Field Output reported at nodes for part: LUG-1 Node U.U2 Label @Loc 1 -------------------------------- 23 -314.158E-06 24 -314.158E-06 143 -314.2E-06 144 -314.2E-06 1522 -314.163E-06 1526 -314.211E-06 1529 -314.163E-06 Minimum -314.211E-06 At Node 1526 Maximum -314.158E-06 At Node 23