Creating the mesh and the job | ||

| ||

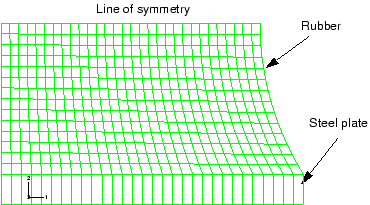

Create a quadrilateral mesh. Seed the part by specifying the number of elements along the edges (by selecting or the  tool). Specify 30 elements along each horizontal edge, 14 elements along the vertical and curved edges of the rubber, and 1 element along the vertical edges of the steel. The mesh is shown in Figure 1.

tool). Specify 30 elements along each horizontal edge, 14 elements along the vertical and curved edges of the rubber, and 1 element along the vertical edges of the steel. The mesh is shown in Figure 1.

Create a job named Mount. Give the job the following description: Axisymmetric mount analysis under axial loading.

Save your model in a model database file, and submit the job for analysis. Monitor the solution progress; correct any modeling errors that are detected, and investigate and correct as necessary the cause of any warning messages.