Initial contact overclosure | ||

| ||

In subsequent steps any nodal adjustments to remove initial overclosures cause strains that often cause severe mesh distortions because the entire nodal adjustments occur in a single, very brief increment. This is especially true when the kinematic constraint method is used. For example, if a node is overclosed by 1.0 × 10−3 m and the increment time is 1.0 × 10−7 s, the acceleration applied to the node to correct the overclosure is 2.0 × 1011 m/s2. Such a large acceleration applied to a single node typically will cause warnings about deformation speed exceeding the wave speed of the material and warnings about severe mesh distortions a few increments later, once the large acceleration has deformed the associated elements significantly. Even a very slight initial overclosure can induce extremely large accelerations for kinematic contact. In general, it is important that in the second step and beyond any new contact surfaces that you define are not overclosed.

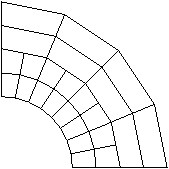

Figure 1 shows a common case of initial overclosure of two contact surfaces. All of the nodes on the contact surfaces lie exactly on the same arc of a circle; but since the mesh of the inner surface is finer than that of the outer surface and since the element edges are linear, some nodes on the finer, inner surface initially penetrate the outer surface.

Assuming that the pure master-slave approach is used, Figure 2 shows the initial, strain-free displacements applied to the slave-surface nodes by Abaqus/Explicit. In the absence of external loads this geometry is stress free. If the default, balanced master-slave approach is used, a different initial set of displacements is obtained, and the resulting mesh is not entirely stress free.