Model data | ||

| ||

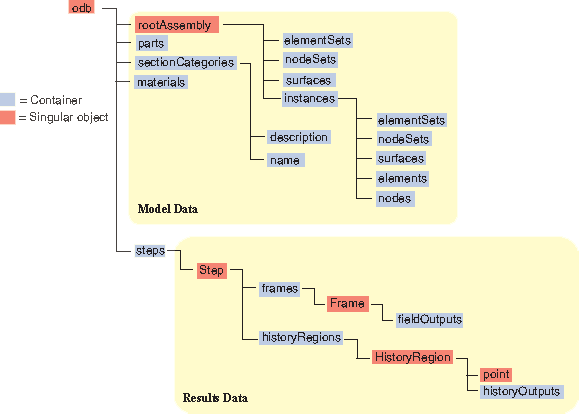

Abaqus does not write all the model data to the output database; for example, you cannot access loads, and only certain interactions are available. Model data that are stored in the output database include parts, the root assembly, part instances, regions, materials, sections, section assignments, and section categories, each of which is stored as an Abaqus Scripting Interface object. These components of model data are described below.

- Parts

A part in the output database is a finite element idealization of an object. Parts are the building blocks of an assembly and can be either rigid or deformable. Parts are reusable; they can be instanced multiple times in the assembly. Parts are not analyzed directly; a part is like a blueprint for its instances. A part is stored in an output database as a collection of nodes, elements, surfaces, and sets.

- The root assembly

The root assembly is a collection of positioned part instances. An analysis is conducted by defining boundary conditions, constraints, interactions, and a loading history for the root assembly. The output database object model contains only one root assembly.

- Part instances

A part instance is a usage of a part within the assembly. All characteristics (such as mesh and section definitions) defined for a part become characteristics for each instance of that part—they are inherited by the part instances. Each part instance is positioned independently within the root assembly.

- Materials

Materials contain material models comprised of one or more material property definitions. The same material models may be used repeatedly within a model; each component that uses the same material model shares identical material properties. Many materials may exist within a model database, but only the materials that are used in the assembly are copied to the output database.

- Sections

Sections add the properties that are necessary to define completely the geometric and material properties of an element. Various element types require different section types to complete their definitions. For example, shell elements in a composite part require a section that provides a thickness, multiple material models, and an orientation for each material model; all these pieces combine to complete the composite shell element definition. Like materials, only those sections that are used in the assembly are copied to the output database.

- Section assignments

Section assignments link section definitions to the regions of part instances. Section assignments in the output database maintain this association. Sections are assigned to each part in a model, and the section assignments are propagated to each instance of that part.

- Section categories

You use section categories to group the regions of the model that use the same section definitions; for example, the regions that use a shell section with five section points. Within a section category, you use the section points to identify the location of results; for example, you can associate section point 1 with the top surface of a shell and section point 5 with the bottom surface.

- Analytical rigid surface

Analytical rigid surfaces are geometric surfaces with profiles that can be described with straight and curved line segments. Using analytical rigid surfaces offers important advantages in contact modeling.

- Rigid bodies

You use rigid bodies to define a collection of nodes, elements, and/or surfaces whose motion is governed by the motion of a single node, called the rigid body reference node.

- Pretension Sections

Pretension sections are used to associate a pre-tension node with a pre-tension section. The pre-tension section can be defined using a surface for continuum elements or using an element for truss or beam elements.

- Interactions

Interactions are used to define contact between surfaces in an analysis. Only contact interactions defined using contact pairs are written to the output database.

- Interaction properties

Interaction properties define the physical behavior of surfaces involved in an interaction. Only tangential friction behavior is written to the output database.

Figure 1 shows the model data object model.

The objects stored as model data in an output database are similar to the objects stored in an Abaqus/CAE model database. However, the output database does not require a model name because an analysis job always refers to a single model and the resulting output database can contain only one model. For example, the following Abaqus Scripting Interface statements refer to an Instance object in the model database:

mdb = openMdb(pathName='/users/smith/mdb/hybridVehicle') myModel = mdb.models['Transmission'] myPart = myModel.rootAssembly.instances['housing']

Similar statements refer to an Instance object in the output database.

odb = openOdb(path='/users/smith/odb/transmission.odb') myPart = odb.rootAssembly.instances['housing']

You can use the prettyPrint method to display a text representation of an output database and to view the structure of the model data in the object model. For example, the following shows the output from prettyPrint applied to the output database created by the Abaqus/CAE cantilever beam tutorial:

from odbAccess import *

from textRepr import *

odb=openOdb('Deform.odb')

prettyPrint(odb,2)

({'analysisTitle': 'Cantilever beam tutorial',

'closed': False,

'description': 'DDB object',

'diagnosticData': ({'analysisErrors': 'OdbSequenceAnalysisError object',

'analysisWarnings': 'OdbSequenceAnalysisWarning object',

'jobStatus': JOB_STATUS_COMPLETED_SUCCESSFULLY,

'jobTime': 'OdbJobTime object',

'numberOfAnalysisErrors': 0,

'numberOfAnalysisWarnings': 0,

'numberOfSteps': 1,

'numericalProblemSummary': 'OdbNumericalProblemSummary object',

'steps': 'OdbSequenceDiagnosticStep object'}),

'isReadOnly': False,

'jobData': ({'analysisCode': ABAQUS_STANDARD,

'creationTime': 'date time year',

'machineName': '',

'modificationTime': 'date time year',

'name': 'Deform.odb',

'precision': SINGLE_PRECISION,

'productAddOns': 'tuple object',

'version': 'Abaqus/Standard release'}),

'name': 'Deform.odb',

'parts': {'BEAM': 'Part object'},

'path': 'C:/Deform.odb',

'rootAssembly': ({'connectorOrientations': 'ConnectorOrientationArray object',

'datumCsyses': 'Repository object',

'elementSet': 'Repository object',

'elementSets': 'Repository object',

'elements': 'OdbMeshElementArray object',

'instance': 'Repository object',

'instances': 'Repository object',

'name': 'ASSEMBLY',

'nodeSet': 'Repository object',

'nodeSets': 'Repository object',

'nodes': 'OdbMeshNodeArray object',

'sectionAssignments': 'Sequence object',

'surface': 'Repository object',

'surfaces': 'Repository object'}),

'sectionCategories': {'solid < STEEL >': 'SectionCategory object'},

'sectorDefinition': None,

'steps': {'Beamload': 'OdbStep object'},

'userData': ({'annotations': 'Repository object',

'xyData': 'Repository object',

'xyDataObjects': 'Repository object'})})

For more information, see prettyPrint(...).