Assembled fasteners vs. point-based fasteners | ||

| ||

- Point-based fasteners

Abaqus looks at the first node of the connector and projects it onto the first surface (given the data line). Abaqus then moves normal to the facet, where it finds the first projection point and finds the subsequent projection points on the second surface.

- Assembled fasteners

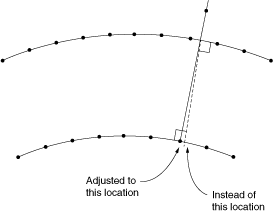

When the assembled fastener is instanced in the main model, Abaqus places the first node of the connector where the first projection point of the point-based fastener model is located. Both fastener types accomplish this placement with normal projections. However, for assembled fasteners an adjust point constraint is performed on the second node of the connector; i.e., a normal projection onto the second surface. This action is not the same as moving normal to the first projection point facet unless the two normals align perfectly. Therefore, the second (subsequent) attachment points can be different for assembled fasteners versus point-based fasteners, which will lead to differences in the analysis solution.

In an ideal case where the two surfaces are placed exactly the same distance apart as the template model connector and are parallel to each other, Abaqus will get the same projection points for assembled fasteners and point-based fasteners. However, this situation will not be the case in general.