What is a display body? | ||

| ||

You can associate the motion of a display body with selected control points (one point or three points), or you can specify that the display body remain fixed during the analysis. If the display body follows a single point, the display body will translate and rotate based on the translations and rotations of the single point. If the display body follows three points, the display body will translate and rotate based on the translation of the three points. For more information, see Display body definition.

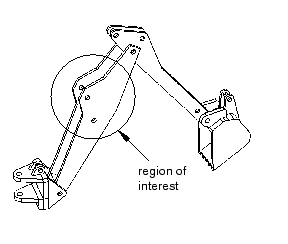

For example, Figure 1 shows a backhoe arm modeled with connectors.

The region of interest is the main arm of the backhoe. The bucket interacts with the rest of the backhoe model only through the connectors and the mass and inertia of the bucket. As a result, the bucket can be modeled as a display body.

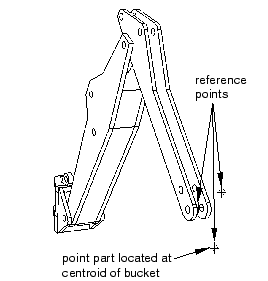

You create a display body by applying a display body constraint to a part instance. For the backhoe arm model you would first create the bucket part instance in the Part module. In addition, you would create a point part and position it at the centroid of the bucket in the assembly, as shown in Figure 2 (see Point parts); a reference point is automatically created for the point part.

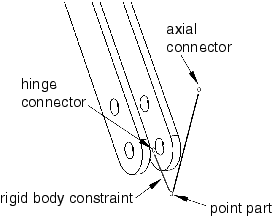

The other two reference points in the assembly serve as endpoints for a HINGE and an AXIAL connector; see Connectors,” for more information on connectors. In the Interaction module you would create a rigid body constraint to constrain the endpoints and the point part to move as a single rigid entity, as shown in Figure 3; see Defining rigid body constraints.

In addition, you would create a display body constraint to constrain the bucket part instance to the point part; see Defining display body constraints.

You do not have to mesh the bucket part instance, and it is not included in the analysis of the backhoe model. However, the bucket still appears when you view the results of the analysis in the Visualization module, as shown in Figure 4.

Display bodies are useful if your model contains a part that cannot be meshed and need not be analyzed. In general, an imported part that has invalid geometry cannot be used by Abaqus/CAE unless you choose to ignore the invalidity of the part (for more information, see Working with invalid parts). If you apply a display body constraint to the invalid part, you can continue to use the part in your model, although the part will not be included in the analysis. For more information, see What is a valid and precise part?.