LE1: Plane stress elements—elliptic membrane | ||

| ||

ProductsAbaqus/StandardAbaqus/Explicit

Elements tested

CPS3

CPS4

CPS4I

CPS4R

CPS6

CPS6M

CPS8

CPS8R

![]()

Problem description

Model:

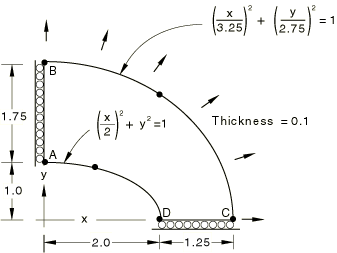

Plane stress problem with shape defined by ABCD. Functions defining the curves BC and AD are given above.

Mesh:

A coarse and a fine mesh are tested for each element. In addition, a very fine mesh is tested for each element in the explicit dynamic analysis.

Material:

Linear elastic, Young's modulus = 210 GPa, Poisson's ratio = 0.3, density = 7800 kg/m3.

Boundary conditions:

along edge AB, along edge CD.

Loading:

Uniform outward pressure of 10 MPa at outer edge BC. In the explicit dynamic analysis the loading is applied such that a quasi-static solution is obtained.

![]()

Reference solution

This is a test recommended by the National Agency for Finite Element Methods and Standards (U.K.): Test LE1 from NAFEMS publication TNSB, Rev. 3, “The Standard NAFEMS Benchmarks,” October 1990.

Target solution: Tangential edge stress () at D is 92.7 MPa.

![]()

Results and discussion

The results are shown in Table 1 and Table 2. The values enclosed in parentheses are percentage differences with respect to the reference solution.

| Element | Coarse Mesh | Fine Mesh |

|---|---|---|

| CPS3 | 51.04 MPa (−45%) | 71.26 MPa (−23%) |

| CPS4 | 66.73 MPa (−28%) | 84.54 MPa (−9%) |

| CPS4I | 58.82 MPa (−37%) | 78.21 MPa (−16%) |

| CPS4R* | 40.48 MPa (−56%) | 56.18 MPa (−39%) |

| CPS6 | 89.10 MPa (−4%) | 94.01 MPa (1%) |

| CPS6M | 85.88 MPa (−7%) | 93.71 MPa (1%) |

| CPS8 | 84.54 MPa (−9%) | 92.81 MPa (0.12%) |

| CPS8R | 85.80 MPa (−7%) | 90.07 MPa (−3%) |

*A comparison of the results for reduced-integration and full-integration lower-order elements indicates that the full-integration elements perform significantly better for problems with stress concentrations of this type.

| Element | Coarse Mesh | Fine Mesh | Very Fine Mesh |

|---|---|---|---|

| CPS3 | 51.2 MPa (−45%) | 71.5 MPa (−23%) | 85.7 MPa (−8%) |

| CPS4R | 39.6 MPa (−57%) | 55.7 MPa (−40%) | 87.3 MPa (−6%) |

| CPS6M | 86.12 MPa (−7%) | 92.93 MPa (−0.2%) | — |

![]()

Input files

Abaqus/Standard input files

Coarse mesh tests:- nle1xf3c.inp

-

CPS3 elements.

- nle1xf4c.inp

-

CPS4 elements.

- nle1xi4c.inp

-

CPS4I elements.

- nle1xr4c.inp

-

CPS4R elements.

- nle1xf6c.inp

-

CPS6 elements.

- nle1xm6c.inp

-

CPS6M elements.

- nle1xf8c.inp

-

CPS8 elements.

- nle1xr8c.inp

-

CPS8R elements.

- nle1xf3f.inp

-

CPS3 elements.

- nle1xf4f.inp

-

CPS4 elements.

- nle1xi4f.inp

-

CPS4I elements.

- nle1xr4f.inp

-

CPS4R elements.

- nle1xf6f.inp

-

CPS6 elements.

- nle1xm6f.inp

-

CPS6M elements.

- nle1xf8f.inp

-

CPS8 elements.

- nle1xr8f.inp

-

CPS8R elements.

Abaqus/Explicit input files

Coarse mesh tests:- le1_cps3_c.inp

-

CPS3 elements.

- le1_cps4r_c.inp

-

CPS4R elements.

- le1_cps6m_c.inp

-

CPS6M elements.

- le1_cps3_f.inp

-

CPS3 elements.

- le1_cps4r_f.inp

-

CPS4R elements.

- le1_cps6m_f.inp

-

CPS6M elements.

- le1_cps3_vf.inp

-

CPS3 elements.

- le1_cps4r_vf.inp

-

CPS4R elements.