Frequency Spectrum | ||

| ||

Overview

Frequency response is obtained using ANTYPE, 3 or ANTYPE,SPECTR in the CDB finite element input deck. The different solution methods for calculating the spectrum in ANSYS® is activated using HROPT. The three following methods are supported in SIMULIA Tosca Structure:

- HROPT,FULL

This is the full solution method.

- HROPT,REDUC

- Reduced solution method (deals only with master nodes, can be viewed as an extension of the Mode Superposition Method)

- By default the reduced solution method writes the reduced results to the

RFRQ file. However, the reduced results have to be expanded to the

entire results in the RST file. Therefore, the following has to be added in

the CDB finite element input file:

- EXPASS,ON for obtaining the response for all nodes.

- NUMEXP for defining the frequency range to be expanded.

- HROUT, ON, OFF, for printing the real and imaginary components (ON is also default) and for uniform spacing of the excitation frequencies (OFF is also default). HROUT, ON, ON for eigenvalue dependent spacing is also allowed.

- HROPT,MSUP

Superposition, the most used option for large models because it is very fast. However, it is requiring that the eigenfrequencies (ANTYPE, 2 and the number of eigenfrequencies) are initially calculated.

Important: Note, that this method can give quite wrong results for low excitation frequencies corresponding to the almost the static load case:

- EXPASS,ON for obtaining the response for all nodes.

- NUMEXP for defining the frequency range to be expanded.

- HROUT, ON, OFF, for printing the real and imaginary components (ON is also default) and for uniform spacing of the excitation frequencies (OFF is also default). HROUT, ON, ON for eigenvalue dependent spacing is also allowed.

![]()

Direct Solution

In the following an example of a part of a load case file (file.s*) using the solution method HROPT,FULL is shown:

......... ANTYPE, 3 ! frequency response ALPHAD, 0.01 ! Viscous mass damping BETAD, 0.02 ! Viscous stiffness damping DMPRAT, 0.03 ! Structural stiffness damping HROPT,FULL ! Direct solution method HROUT,ON,OFF ! Uniform spacing (default) NSUBST, 405 ! Number of substeps HARFRQ,0,500 ! Frequency range OUTPR,ALL,NONE ! No output in ASCII format .........

Below an example of a part of a CDB file using load cases based on

HROPT,FULLis shown:

................ /GO FINISH ! --------------------------------------------------- /SOLU HROUT,ON,OFF ! Both real and imaginary part OUTPR,ALL,NONE ! No output in ASCII format LSSOLVE,1,1,12 ! In this case 12 load cases FINISH ................

![]()

Modal Decomposition

In the following an example of a part of a load case file (file.s*) using the solution method HROPT,MSUP (or HROPT,REDUC) is shown:

......... ANTYPE, 3 ! frequency response ALPHAD, 0.01 ! Viscous mass damping BETAD, 0.02 ! Viscous stiffness damping DMPRAT, 0.03 ! Structural stiffness damping HROPT,MSUP,25,1 ! Mode superposition method HROUT,ON,OFF ! Uniform spacing (default) NSUBST, 405 ! Number of substeps HARFRQ,0,500 ! Frequency range OUTPR,ALL,NONE ! No output in ASCII format .........

An example of a part of a CDB file using load cases based on HROPT,REDUC or HROPT,MSUP is shown below.

Note:

The CDB file should have the name model.cdb in this example. If another filename for the CDB file is applied, then the file name "model" should be substituted with the other file name.

In the given example, the frequency range is going from 0 Hz to 500 Hz using 105 increments. The user can also apply NUMEXP,ALL.

.......... /GO FINISH ! --------------------------------------------------- ! Modal (Eigenfrequency) solution /SOLU LSSOLVE,1,1,1 /COPY,file,rst,,model_1,rst FINISH ! --------------------------------------------------- ! Frequency response solution ! --------------------------------------------------- ! Loadcase 2: Frequency response 1 ! use the results of the modal analysis /SOLU /COPY,model_1,rst,,file,rst LSSOLVE,2,2,1 FINISH ! expansion of the solution /SOLU /assign,rst,model_2,rst EXPASS,ON OUTPR,ALL,NONE ! No output in ASCII format NUMEXP, 105, 0.0, 500.0 ! the frequency range to expand HROUT,ON,OFF ! both real and imaginary part SOLVE FINISH ! --------------------------------------------------- ! Loadcase 3: Frequency response loadcase 2 ! use the results of the modal analysis /SOLU /COPY,model_1,rst,,file,rst LSSOLVE,3,3,1 FINISH ! expansion of the solution /SOLU /assign,rst,model_3,rst EXPASS,ON OUTPR,ALL,NONE ! No output in ASCII format NUMEXP, 105, 0.0, 500.0 ! the frequency range to expand HROUT,ON,OFF ! both real and imaginary part SOLVE FINISH ! --------------------------------------------------- ! Loadcase 4: Frequency response loadcase 3 ! use the results of the modal analysis /SOLU /COPY,model_1,rst,,file,rst LSSOLVE,4,4,1 FINISH ! expansion of the solution /SOLU /assign,rst,model_4,rst EXPASS,ON OUTPR,ALL,NONE ! No output in ASCII format NUMEXP, 105, 0.0, 500.0 ! the frequency range to expand HROUT,ON,OFF ! both real and imaginary part SOLVE FINISH ..............

Important:

|

![]()

The General Damping Matrices in ANSYS®

The general damping matrix [C] of the structure can be written as

with

| = | structural stiffness matrix |

| = | structural mass matrix |

| = | circular excitation frequency |

| = | mass matrix multiplier for viscous damping (input in ANSYS using the ALPHAD command) |

| = | stiffness matrix multiplier for viscous damping (input in ANSYS using the BETAD command) |

| = | variable stiffness matrix multiplier for structural damping Important note: for modal superposition is DMPRAT modal damping and therefore NOT allowed. |

| = | stiffness matrix multiplier for material j for viscous damping (input as a material property using the DAMP label on the MP command) |

| = | is the number of materials with DAMP Note: this number should include all elements in the design domain and in the manufacturing constraints. |

| = | stiffness matrix coefficient for material j for structural damping (input as DMPR on MP command) |

| = | element damping matrices in general form (are always permissible) |

| = | eigenfrequency dependent damping matrix Note: not supported, damping defined through MDAMP is prohibited |

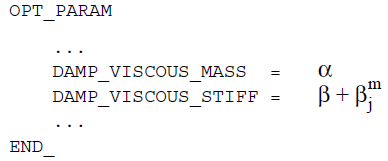

Allowable viscous damping for design elements in ANSYS®:

Allowable structural damping for design elements in ANSYS®: