Check run (TEST_SHAPE) | |||||||

|

| ||||||

General

Before beginning an optimization, it is advisable to check the output file (TOSCA.OUT) of the optimization preprocessors for any possible warnings or errors. If the optimization preprocessing has been performed without error, the user has the option of carrying out a test run for the shape optimization without a prior FE analysis. This is done by applying pseudo 'optimization displacements'. This option enables the user to quickly and easily check if the mesh smoothing and the restrictions are fully defined and will deliver the desired results. The above procedure is especially recommended for link conditions. The following are typical questions that such a test run can answer:

- Is the design area, i.e., the design nodes, selected correctly?

- Is the MESH_SMOOTH area too small or too large?

- Is the selected transition area between the design area and the border of the MESH_SMOOTH area in order?

- Will all of the restrictions be fulfilled (displacement directions, amount of displacement, contact against solids or elements, link conditions)?

- Will any nodes be moved by MESH_SMOOTH although they should not be modified, so that additional restriction of these nodes is needed?

The results of the test run are sent to user-defined files that can be subsequently loaded into a suitable postprocessor for evaluation. This allows the test results to be easily displayed and checked. If the results of the test run are not satisfying, the optimization model may need to be modified. The effort required to perform a test run in the optimization preprocessor is much less than the effort required for a complete optimization. Unwanted side effects can make a ‘costly’ and time-consuming optimization useless although the side effects might have been recognized without much effort in a test run.

![]()

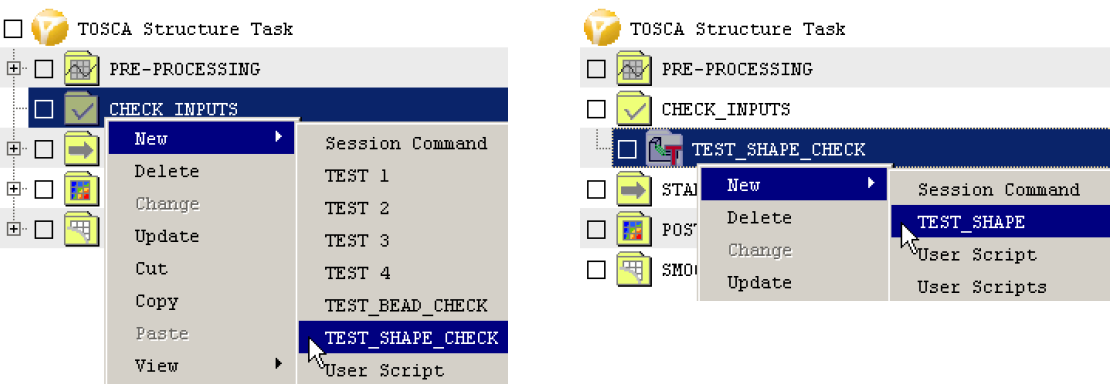

Test run (CHECK_INPUTS) in Tosca ANSA® environment

- Select CHECK_INPUTS item of Task Manager.

- First apply command on CHECK_INPUTS item.

- Apply command on TEST_SHAPE_CHECK item.

- The test is performed when Update command is applied on the created TEST_SHAPE item. The results are opened in Tosca Structure.view using the item VTF_VISUALIZATION that is also created below TEST_SHAPE_CHECK.

|

![]()

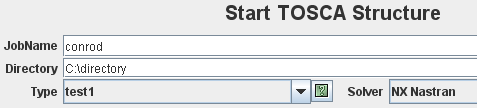

Test run in Tosca Structure.gui

- To define your test displacements in Tosca Structure.gui, choose the command mask.

- To start the test run, start SIMULIA Tosca Structure with Type = test1.

- Create your visualization sequence using Tosca Structure.report.

|

![]()

Command syntax

The test run in the shape optimization is controlled by the TEST_SHAPE command. A test run is always based on a previously defined optimization job that is referenced in the OPTIMIZE command. The format information for the postprocessing is specified with the FORMAT parameter. The name of the file into which the postprocessing data is written is specified with the FILE_NAME parameter. The test displacement in a specified direction (DIRECTION) is applied in a specified number of increments (INCREMENT parameter) until reaching a maximum displacement (DISPLACEMENT parameter).

A typical TEST_SHAPE command appears as follows:

TEST_SHAPE OPTIMIZE = <name_of_optimize> FORMAT = ONF FILE_NAME = <name_of_output_file> DIRECTION = [ GROW | SHRINK | RANDOM ] DISPLACEMENT = <value_of_max_displacement> INCREMENT = <number_of_increments> END_

- If all the information entered by the user is correct, the TEST_SHAPE command is executed immediately after it is entered. The command does not have its own name with which it can be referenced and all command data are only temporarily active during the execution of the command.

- The referencing of a previously defined optimization task (OPTIMIZE command) is mandatory. The test displacements are applied to the design nodes of the optimization job.

![]()

Specifications

- Specification of a file name (FILE_NAME parameter)

is optional. By default the file name TEST_SHAPE is

used. An increment number is always attached to the file names (for example,

000, 001, 002 etc.) to enable identification of the results from the

various increments.

Note: The automatic creation of the vtfx report requires the use of the default file name TEST_SHAPE.

- Specification of a displacement direction (DIRECTION parameter) is optional. The default setting is GROW. Three possibilities can be selected in specifying the displacement direction: uniform growth of all design nodes in the optimization group outwards (DIRECTION=GROW), uniform shrinkage of all design nodes in the optimization group inwards (DIRECTION=SHRINK) or non-uniform ‘randomly controlled’ displacement of the design nodes in the optimization group (DIRECTION=RANDOM).

- Because uniform displacements are applied with DIRECTION=GROW or SHRINK, it may occur that LINK_SHAPE conditions will be insufficiently tested due to the fact that LINK_SHAPE conditions (conditional on the uniform displacements) may be fulfilled a priori. If the optimization job contains LINK_SHAPE conditions, it is recommended to apply non-uniform displacements using DIRECTION=RANDOM. This will allow the correct operation of the LINK_SHAPE conditions to be tested.

- Specification of the maximum amount of displacement (DISPLACEMENT parameter) is optional. If no maximum amount of displacement is specified by the user, then a maximum amount of displacement dependent upon the measurements of the FE mesh will be automatically determined.

- Specification of a number of increments (INCREMENT parameter) is optional. The default value is INCREMENT=1. If the user specifies 5 increments, for example, 6 results files are generated, whereby the first result file with the file extension ‘000’ represents the initial state.

- If DIRECTION=RANDOM is selected, it is possible that the design node with the maximum displacement will have a smaller amount of displacement than is specified in the DISPLACEMENT parameter. Here, the maximum specified displacement only represents an upper limit that does not need to be achieved due to the ‘randomly controlled’ distribution of the displacements.

![]()

Example

The optimization task named shape_optimization should be subjected to a test run. The file names are to have the name test_grow. In the growth direction five displacement increments should be applied with a maximum displacement of 1.5 length units, i.e. the displacements are applied in increments of 0.0, 0.3, 0.6, 0.9, 1.2 and 1.5.

TEST_SHAPE OPTIMIZE = shape_optimization FILE_NAME = test_grow DIRECTION = GROW DISPLACEMENT = 1.5 INCREMENT = 5 END_