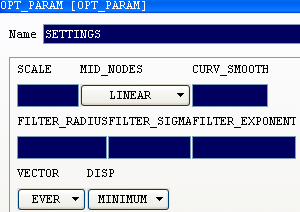

Settings for controller based shape optimization | |||||||

|

| ||||||

The user can set several optimization parameters using the OPT_PARAM command and thereby influence the controller response.

- In Tosca ANSA® environment,

the settings are available in the task manager (

command on SHAPE_OPTIMIZATION_CONTROLLER item) or using

the OPT_PARAM button in the modules buttons.

- In Tosca Structure.gui, the settings are defined in OPT_PARAM command.

Each OPT_PARAM command has a unique name (ID_NAME parameter) and references a previously defined optimization job (OPTIMIZE command). The specified parameters only relate to the given optimization task. A typical OPT_PARAM command appears as follows:

OPT_PARAM ID_NAME = param_for_shape_optimization OPTIMIZE = shape_optimization ... END_

Six parameters can be set by the user for shape optimization:

- Scaling of the allowed amount of displacement

- Treatment of the midside nodes during the optimization

- Curvature based modification of the optimization movement vector

- Filtering of the optimization displacements

- Updating of the normal vectors (optimization displacement vector)

- Control of the increments according to the allowed displacements

Note: The OPT_PARAM command is also used in topology optimization. However, the optimization parameters that can be set depend on the type of optimization. The only parameters that can be set here are those allowed for shape optimization.

Scale of displacement (SCALE)

The controller provides an automatic increment control of the optimization displacements. An initial increment is first determined based on the mesh of the FE start model. The size of the increment is then automatically adjusted in every design cycle. Usually, the user does not need to modify the increment control manually. The user can increase or decrease the increment using a scaling factor (SCALE parameter):

... SCALE = <REAL_value> ...

The default setting is SCALE=1.0, i.e. the optimization displacements are applied in increments determined by the controller. If the selected scaling factor has a value greater than one, the increment size determined by the controller will increase correspondingly, i.e. the optimization is accelerated. On the other hand, if the selected scaling factor has a value less than one, the increment size determined by the controller will decrease accordingly, i.e. the optimization is slowed down.

Example: With SCALE=2.0 the increment size as determined by the controller is doubled. With SCALE=0.8 the increment size of the controller is reduced to 80% of the initial increment size.

The scaling factor can be split in a factor for growth and a factor for shrinkage:

... SCALE = <grow_value>, <shrink_value> ...

Important:

|

![]()

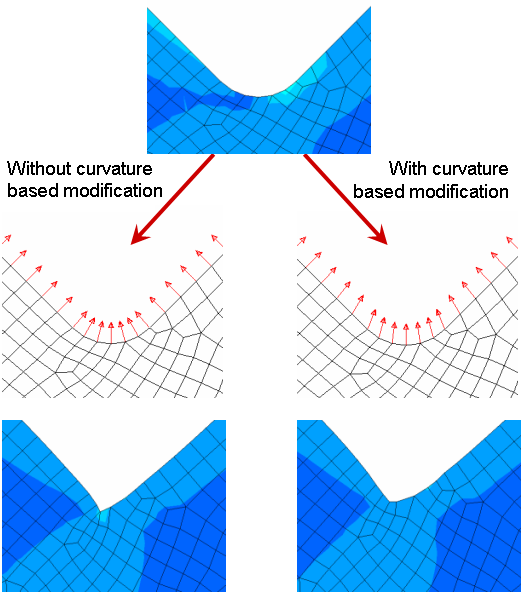

Curvature based modification of optimization displacements

The nodal optimization movement vector is modified in areas of high curvature to prevent a collapse of the mesh for large volume changes (CURV_SMOOTH). A bigger radius causes a bigger curvature based modification of the optimization movement vector. (Default=5.0 * element edge lengths; OFF=0.0)

... CURV_SMOOTH = 5.0 ...

|

![]()

Filter function for the optimization displacements (FILTER)

To smooth local peaks of the nodal reference stresses, the item FILTER can be specified to activate a filter function:

... FILTER = <radius>, <sigma>, <exponent> ...

The filter is given by:

is the filter value for node j. The main filter function (B) decreases with the distance (d) between node i and j. The maximal radius () defines the maximum distance for the nodes i to influence the filter value. The curvature dependency () defines a weight function to reduce the radius at higher local surface curvature () approximated by the vector product of the node normal () to the neighboring nodes ().

SIGMA () and EXPONENT (p) are optional with the default values (0.2 and 1., respectively). The smaller the SIGMA, the larger is the influence of the surface curvature. To avoid this effect, use a large SIGMA value (e.g. 10000).

The exponent value defines the weight function which controls the influence depending on the distance from the node.

To smooth local peaks of the nodal reference stresses, use the DRESP OPER=FILTER which gives the user the possibility to define filters that correspond to single design responses. Example:

DRESP ID_NAME = DRESP_MISES_FILTERED DEF_TYPE = OPER VAR_OPER = FILTER VAR_A = DRESP_MAX_MISES RADIUS = 30.0 EXPONENT = 1.0 SIGMA = 1.0 END_

The parameters RADIUS, EXPONENT and SIGMA have the same meaning as in the filtering of nodal displacements.

| Important: Large values of RADIUS may increase CPU-time. |

![]()

Control of the amount of optimization displacement (DISP)

Based on the current FE mesh, an allowed amount of displacement is determined for every design node. This displacement variable limits the amount of the optimization displacement, i.e. optimization displacements that are greater than the allowed displacements are scaled back automatically to the allowed value node by node. This is intended for avoiding the collapse of a neighboring element when having a large optimization displacement of one node.

The controller provides automatic increment control of the optimization displacements. The increment size is dependent on the allowed displacements of the design nodes. A decrease of the allowed displacements (a decrease in the quality of the FE mesh) automatically leads to a decrease in the increment size of the controller. The increment size of the controller is automatically adjusted in every design cycle.

The DISP parameter enables the user to specify which allowed displacement is to be used in the increment control:

... DISP = [ MINIMUM | AVERAGE ] ...

DISP=AVERAGE is the mean value of the allowed amount of displacement for the design nodes used in the increment control; DISP=MINIMUM (default) is the smallest value used. The setting DISP=AVERAGE delivers a larger increment size and consequently a faster approximation to the optimum. However, this opens for the possibility that nodes for which only small displacements are allowed move too little causing ‘undesirable corners’ in the design area.