The controller-based bead optimization (BEAD_CONTROLLER) is based upon a special bending hypothesis developed at IPEK at Karlsruhe University.

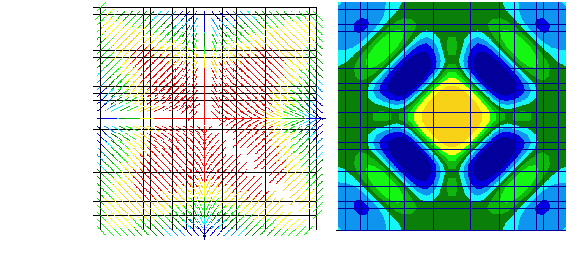

It determines the orientation of the maximum bending stress or Differential Stress Tensor (DST) for each point in the design domain.

The Differential Stress Tensor (DST) is the difference tensor between the stress tensors at the top and at the bottom shell layer.

The emerging bead flanks are oriented parallel to the DST eigenvectors.

Special filters are used to generate these beads along the bending trajectories.

This method has the following advantages:

- Solver-independent and sensitivity-independent

- mesh-independent

- clear results

- restrictions on the bead form can be included