General Information | ||

| ||

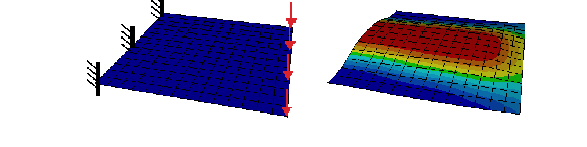

The easiest way to understand bead optimization is a simple example every mechanical engineer will intuitively understand.

|

In the above figure is a simple flat plate in bending shown. It is evident that the solution on the right side has a much greater stiffness than the original flat plate on the left.

Regarding this simple example a couple of comments must be made:

|

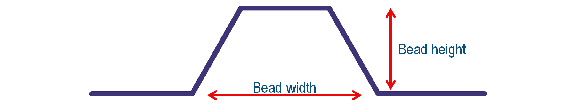

The bead height (see figure above) has the most significant effect on the stiffness of the plate structure. Usually, the greater the bead height the greater the stiffness. But, the bead height is usually controlled by manufacturing capabilities i.e how deep can you draw a bead with your available tools.

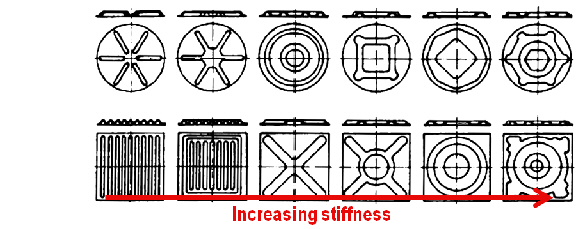

The bead width has an effect on the possible designs. As seen in the figure below (taken from Oehler and Weber: "Steife Blech- und Kunststoffkonstruktionen", Springer-Verlag GmbH (1972)) a small or a large bead width is not necessarily related to the stiffness of the sheet structure. The SIMULIA Tosca Structure.bead default values usually suffice, but if an optimal solution is sought you must try more bead widths.

|

The figure also shows that for more complex loads or dynamic problems i.e. eigenvalue or frequency response, the optimal bead layout is not intuitive anymore. Thus, an easy way to find a good bead pattern is to use SIMULIA Tosca Structure.bead.