About Minimizing a Reaction or Internal Force | ||

| ||

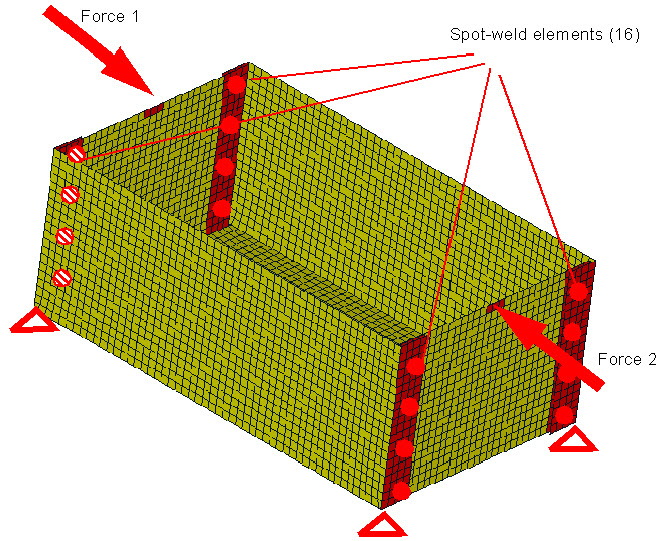

A simple box model with 16 spot-weld elements is optimized.

|

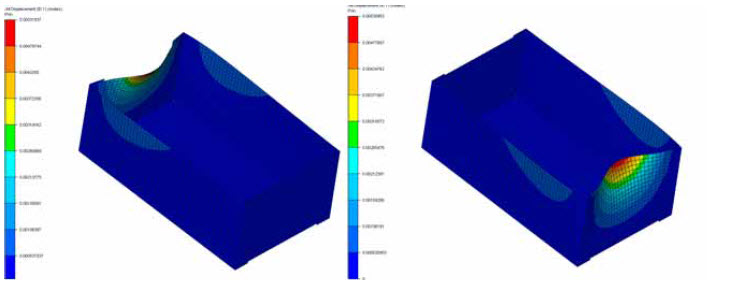

Displacement plots for load cases 1 and 2 are pictured in the following figure.

|

The box is loaded with 2 forces on the two sides. The edges of the bottom rectangle are fixed.

Formulation of the Optimization Problem

The optimization problem can be formulated in different ways:

- The first possible formulation is to minimize the maximum spot-weld force under a volume constraint. The second formulation is to minimize the volume while restricting the forces in the spot-weld elements. Additionally, a displacement constraint is applied.

- The second formulation is presented in the following:

with Vol being the relative material volume of the design area, the nodal force in an element in a given direction, the constraint force, the nodal displacement and the restriction for the nodal displacement.

![]()

Necessary Definitions

Four design responses are needed in order to set up the optimization task.

- The first design response is the relative material volume of the design area. This relative material volume design response is then used in the objective function that is to be minimized.

- The second design response is the maximum internal force over the nodes of a given node group belonging to the elements mentioned in the given element group.

- The third and fourth design responses are the displacements of the loaded nodes that are then used in constraints. These design responses are defined as the total displacements for each load case and the appropriate loaded node.